Several classification methods for shoelace tying machines

Release time:

2022-02-13

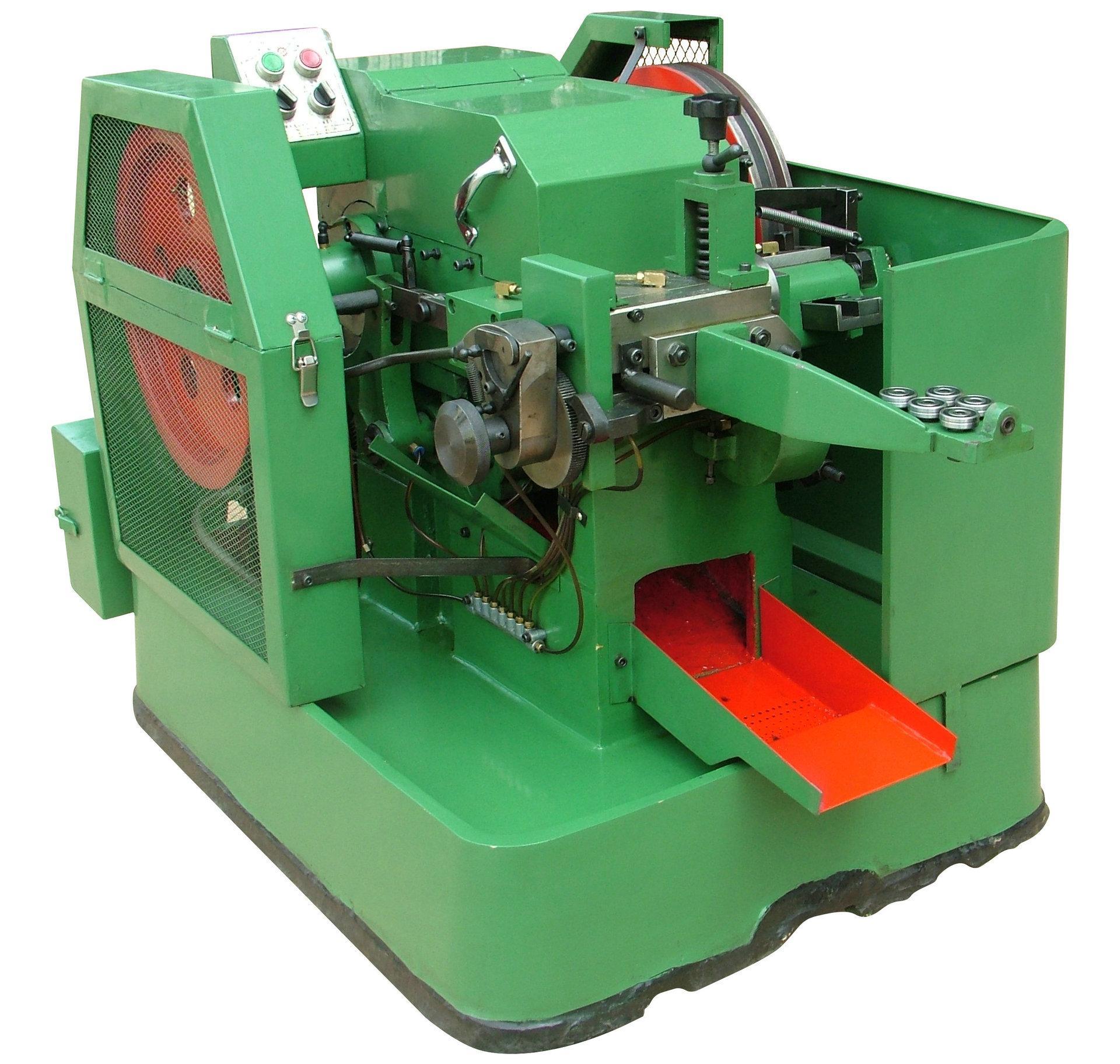

The shoelace header machine is divided into shoelace header machines and screw header machines based on the industry in which it is used. In general usage, they can be combined in any way and typically do not appear in an independent form. For example, the header machine that feeds glue shoes to semi-automatic single-blade machines, the header machine that feeds glue shoes to fully automatic double-blade computers, and the header machine that feeds rubber gifts to fully automatic double-blade machines. Now, let's learn about the various classification methods of shoelace header machines!

The shoelace end machine is divided into shoelace end machines and screw end machines based on the industry in which it is used. In general usage, they can be combined in any way and usually do not appear in an independent form. For example, the semi-automatic single-blade machine sends glue shoes to the end machine, the fully automatic double-blade computer sends glue shoes to the end machine, and the fully automatic double-blade machine sends rubber gifts to the end machine. Let's learn about the various classification methods of the shoelace end machine together!

The classification of the shoelace end machine is divided into the following types based on the operation mode and the degree of mechanical automation:

1. Semi-automatic searching machine: The semi-automatic shoelace searching machine requires manual material input, manual length control, and manual control of the machine's end action. It has the advantages of high flexibility and convenient length adjustment, making it suitable for small-scale production and sample making. The output and quality are directly related to the workers.

2. Fully automatic headset: The fully automatic shoelace headset differs from the semi-automatic one in that its degree of automation is very high. Feeding, length control, quantity statistics, and the machine's head action are all done automatically, and workers only need to take out the finished products for packaging. Importantly, it is suitable for mass production. The output of the fully automatic headset is very high, reaching about 60,000 pieces per day.

The shoelace end machine can be divided into single-blade end machines and double-blade end machines based on the working mode.

1. Single-blade end machine: Only one blade is used in the middle of the mold for the end, directly connecting in the middle of the finished product.

2. Double-blade end machine: Two blades are used in the middle of the mold for the end, simultaneously cutting the rope.

Based on the gum delivery mode:

1. Mechanically delivering glue.

2. Sending glue to the computer.

Shoelace end machine by product type:

1. Shoelace cap printing machine.

2. Gift earphones.

Those engaged in shoelace end machines all know that this machine is imported, but where are their main technical advantages? Today, let's talk about the patent features of the shoelace end machine.

The shoelace end machine is equipped with a positioning wheel system and a positioning pneumatic fixture on one side, with a cutting device on one side of the positioning pneumatic fixture. Above it is a shoelace end machine with a sliding base linked by a cylinder. The cutting device's mold base has a retractable main blade and side blade; other cylinders are installed on the sliding base, and a material clamping disc that can be displaced through set control is connected to the retractable rod. The cylinder can make the material clamping disc move up and down through set control; through the feeding pneumatic fixture and positioning pneumatic fixture, the shoelace can be placed into the cutting device through set control, and the main and side blades can automatically cut off the shoelace tips.

One side is equipped with a positioning wheel system and a positioning pneumatic fixture machine, and on one side of the positioning pneumatic fixture, there is a cutting device. Above it is a shoelace end machine with a sliding base linked by a cylinder. It is characterized by having a retractable main blade and side blade on the mold base of the cutting device. The bottom bevel angle of the main blade has other cylinders on the sliding base, and the retractable rod is connected to an input pneumatic chuck that can move left and right through set control. The cylinder can make the incoming pneumatic chuck move up and down through set control, positioning the incoming pneumatic chuck, and displacing between the pneumatic chuck and the cutting device. Through the feeding pneumatic fixture and positioning pneumatic fixture, the shoelace can be placed into the cutting device, and the main and side blades of the cutting device can automatically cut off the shoelace tips according to the set protrusion.

The above introduces several classification methods of the shoelace end machine. If you want to know more, you can always Contact Us!

Latest News