How should the cold heading machine be maintained on a daily basis?

Release time:

2021-05-19

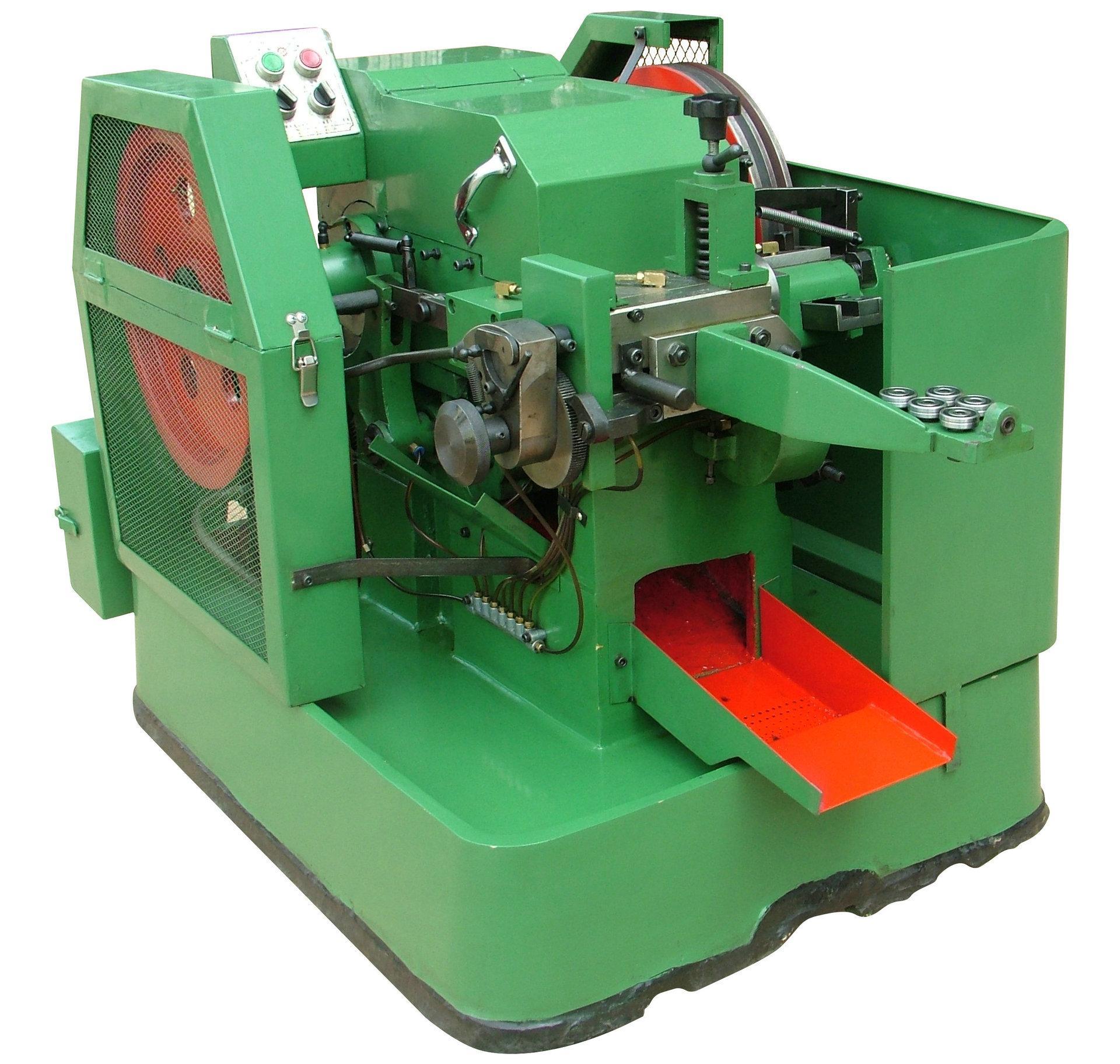

The cold heading machine is a specialized device for mass production of fasteners such as nuts and bolts, primarily based on bridge piers. The cold heading machine forms cold heading at room temperature, with good surface finish, high precision, and excellent strength performance. The cold heading technology uses molds to directly form metal wire in one go, operated by a robotic arm, greatly improving production efficiency and safety.

Cold heading machineIt is a specialized equipment for mass production of fasteners such as nuts and bolts, mainly based on bridge piers.Cold heading machineCold heading is formed at room temperature, with good surface finish, high precision, and excellent strength performance. The cold heading technology uses molds to directly form metal wire in one go, operated by a robotic arm, greatly improving production efficiency, safety, and reliability.

Cold heading machineHow should daily maintenance be carried out? Simple maintenance mainly involves regular cleaning, which can be done through wiping and lubrication methods to maintain the performance and technical status of the equipment.:

1The most basic cleaning requirement for the cold heading machine is that every corner must be thoroughly cleaned, including the rack, gearbox, and oil holes, and surrounding debris must also be cleared away before lubrication.

2Tools and accessories should be placed in the correct position, and the lines should be organized.

3Lubricating oil should be replaced regularly, and cold heading oil should be added when insufficient to avoid running out of oil, which can cause significant damage to the machine.

4The cold heading machine should be operated under safe conditions, following the correct operating methods, avoiding overload, and conducting regular inspections. If a fault occurs, the root cause should be identified and resolved promptly. Regular maintenance can also extend the product's lifespan.

Incorrect processing methods can lead to cold heading machine failures. Below are common faults of the cold heading machine and their solutions.:

1Before starting, carefully check whether the fasteners of the equipment are tightened, and whether the safety protection devices are intact. Loose parts due to severe vibrations during operation can also cause failures, so regular checks during work are necessary.

2After adjusting the equipment, first pull the flywheel to check whether each mechanism is working normally. After removing the wrench lever, start the motor to see if the machine is operating normally.

3Add protective devices to prevent rupture accidents.

4In case of a fault, immediately stop the cold heading machine, identify the cause, and eliminate potential hazards.

Latest News