Introduction to the main functions and performance of shoelace tying machines

Release time:

2022-01-14

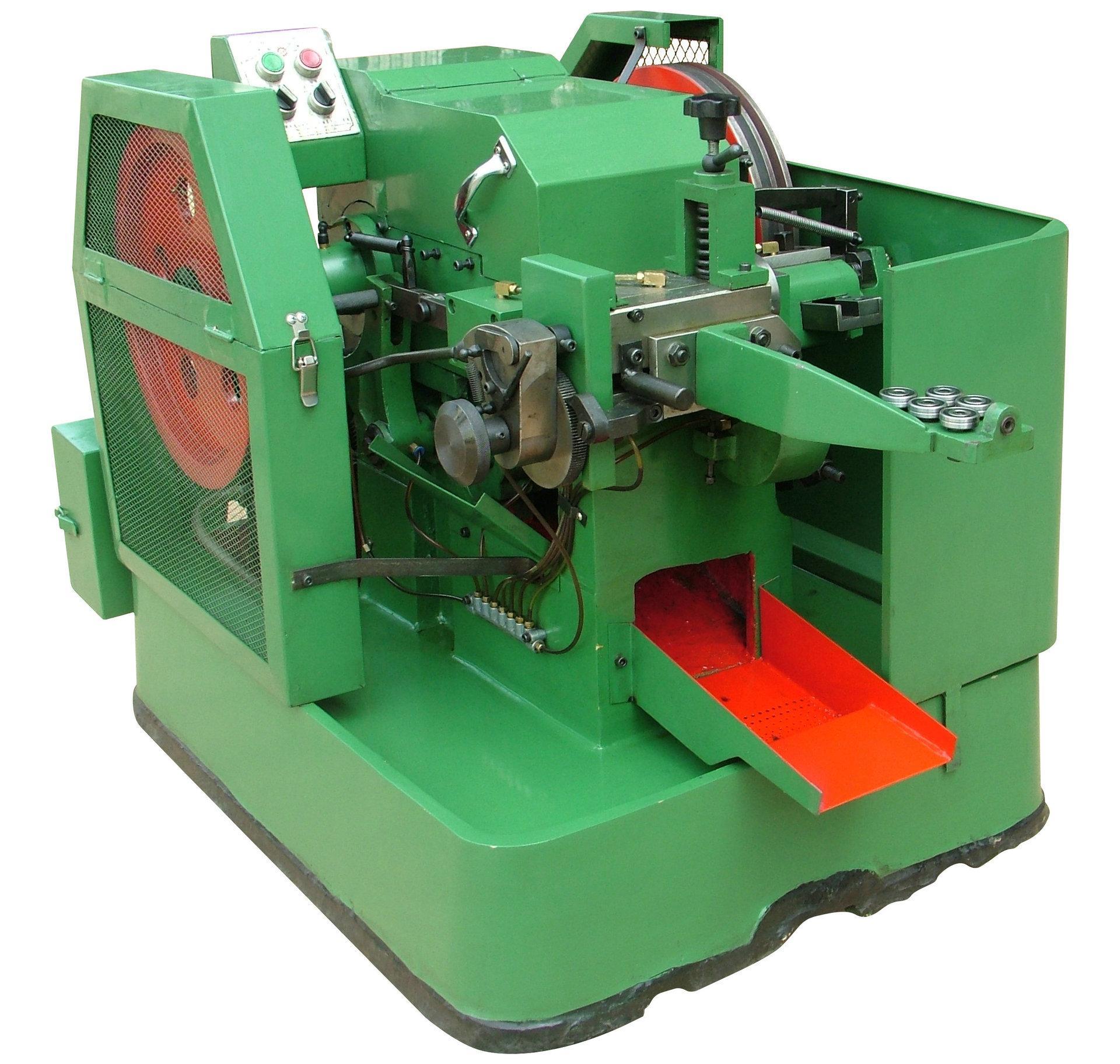

The shoelace tip machine is a manually fed material, with manual control over length and the machine's tip action. It has the advantages of high flexibility and convenient length adjustment, making it suitable for small-scale production and sample making. The output and quality are directly related to the workers. The fully automatic shoelace tip machine, unlike the semi-automatic version, has a high degree of automation. Feeding, length control, quantity statistics, and the machine's tip action are all performed automatically, allowing workers to simply take out the finished products for packaging. Now, let's learn about the main functions and performance of the shoelace tip machine!

The shoelace end machine is manually fed with materials, manually controls the length, and manually controls the machine's end capping action. It has the advantages of high flexibility and convenient length adjustment, suitable for small-scale production and sample making. The output and quality are directly related to the workers. The fully automatic shoelace end machine, unlike the semi-automatic one, has a high degree of automation, with feeding, length control, quantity statistics, and machine end capping actions all performed automatically. Workers only need to take out the finished products for packaging. Now, let's understand the main functions and performance introduction of the shoelace end machine together!

The main functions of the shoelace end machine are two:

1. To cap the ends of the shoelaces;

2. To cut and process the shoelaces to a certain length. Therefore, based on the working mode, it is divided into single-blade shoelace end machines and double-blade shoelace end machines. As the name suggests, the single-blade machine uses only one tool in the middle of the mold for capping, directly connecting in the middle of the finished product. On the other hand, the double-blade end machine uses two tools in the middle of the mold for capping while cutting the rope.

The shoelace end machine is divided into semi-automatic shoelace ejecting machines and fully automatic shoelace ejecting machines based on the operating mode. The semi-automatic shoelace end machine is manually fed with materials, manually controls the length, and manually controls the machine's end capping action. It has the advantages of high flexibility and convenient length adjustment, suitable for small-scale production and sample making. The output and quality are directly related to the workers. The fully automatic shoelace end machine, unlike the semi-automatic one, has a high degree of automation, with feeding, length control, quantity statistics, and machine end capping actions all performed automatically. Workers only need to take out the finished products for packaging. Importantly, it is suitable for mass production. The output of the fully automatic machine is very high, reaching about 60,000 units per day.

Introduction to the maintenance of the shoelace end machine:

The use of the shoelace end machine is relatively simple, but we also need to understand relevant knowledge, which helps with daily maintenance. Here, we mainly introduce the maintenance knowledge of the shoelace end machine.

1. The temperature of the shoelace end machine will be automatically adjusted. Usually between 50 and 60, it adjusts the temperature by itself when it reaches the set value.

2. Main motor overload protection function.

3. Install special safety devices, long mold life.

4. Sturdy structure, safe operation.

5. To prevent reverse phase damage to structural components, there is a phase sequence protection function. The machine cannot start when the wiring is reversed and needs to be replaced.

6. It has a no-film automatic stop function to prevent the machine from idling and reduce losses.

The above introduction is the main functions and performance introduction of the shoelace end machine. If you need to know more, feel free to Contact Us!

Latest News