Characteristics of the structure of the punching machine

Release time:

2021-12-30

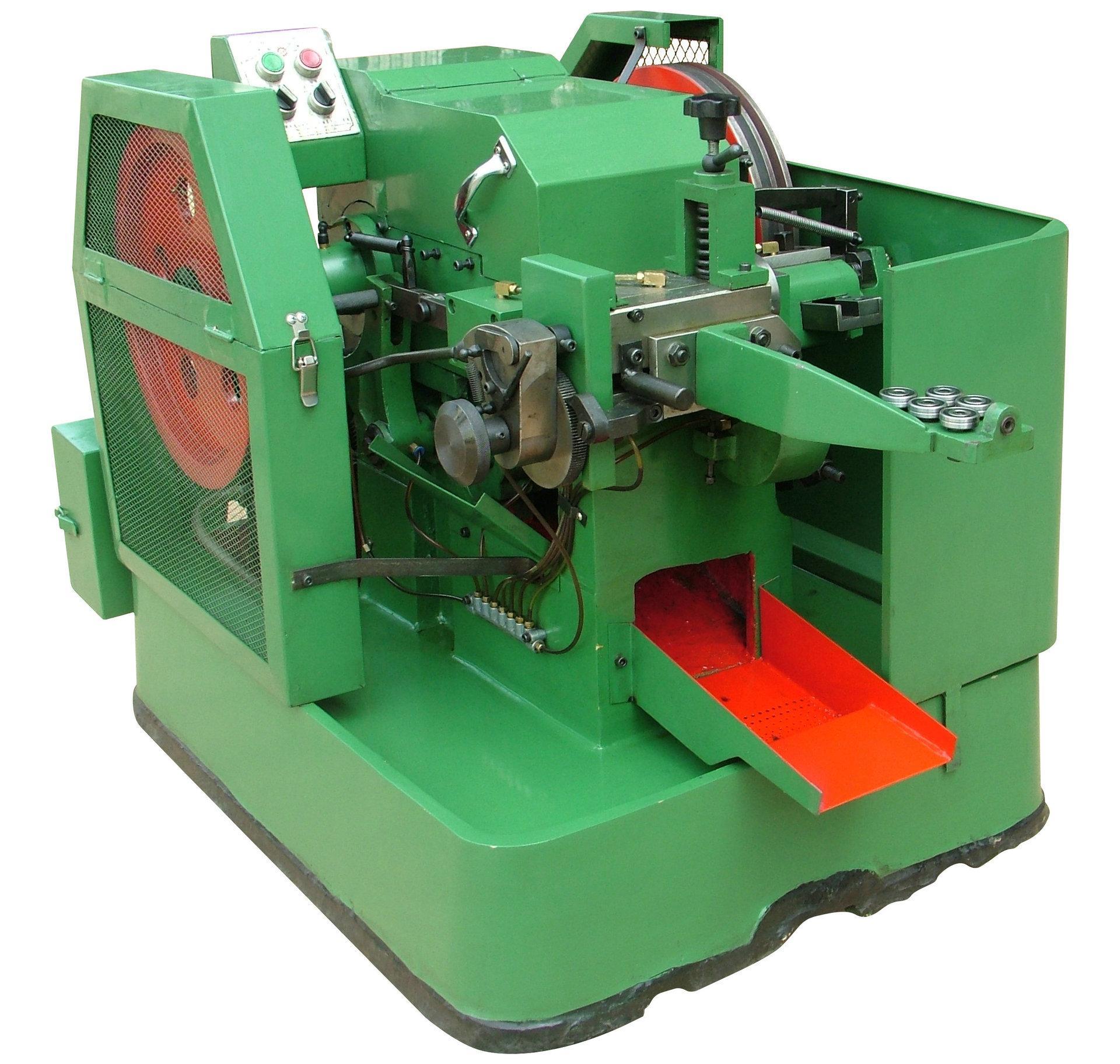

The heading machine is a cold forging device, whose function is to allow a mold and two products to circulate. It is mainly used for the head forming of threaded products and can forge various metal materials such as ordinary steel, carbon steel, stainless steel, copper, aluminum, and alloy steel, making it widely applicable. The machine can produce common products such as ordinary self-tapping screws, electric screws, micro screws, internal hexagon and external hexagon screws, drill screws, fiberboard screws, etc. Now, let's learn about the structural characteristics of the heading machine!

The heading machine is a cold forging device, its function is to allow a mold and two products to circulate. It is mainly used for the head forming of threaded products and can forge various metal materials such as ordinary steel, carbon steel, stainless steel, copper, aluminum, and alloy steel, making it widely applicable. The machine can produce ordinary products such as self-tapping screws, electric screws, micro screws, internal hexagon and external hexagon screws, drill screws, fiberboard screws, etc. Now let's learn about the structural characteristics of the heading machine!

The structure and performance of the heading machine are determined by the working principles of wire drawing adjustment, feeding, cutting, and feeding into the main mold, one punch and one forging, as well as the two punches forming the blank. Its work is completed in one go, with a production capacity of up to 200 pieces per minute, which is currently a relatively advanced product.

The structural characteristics of the heading machine, the heading machine is a type of screw head for screws, such as hex holes, hex holes, and external hexagons, cross types, etc. The structure of the machine is to place the wire material into the machine, the machine sets the type and length of the cutting head, and the punch frame drives the cut of the threaded head to form the head shape. The punch seat of the punching unit is equipped with at least a material reset mechanism consisting of a material reset rod, force application component, crank component, shaft support component, swinging component, sliding component, fixed frame, and sliding plate.

Heading machine operation Specification

Before operating the heading machine, hand over the work, understand the materials, equipment, quality, etc. produced by the previous shift, check the equipment according to the daily maintenance content, and Confirm that everything is correct before starting the machine. Carefully check the content of the metal plate and process card, and select the appropriate mold.

Heading machine unit:

Connect A: main power supply, release the emergency stop button, and the warning light will illuminate. Start the oil pump, and the switch should be in the automatic position.

Change B: When changing the mold, be sure to press the emergency stop button to shut down.

C: Adjust the stroke reasonably according to the size of the pipe material to avoid excessive hydraulic stroke idling. Adjust once for each specification produced.

D: Place the pipe material into the fixture, but it should not be too long. The flat mold is just right, and the length of the pipe head is determined by the size of the specification.

E: The foot switch must be intact, please do not disassemble it.

Heading machine shrink tube:

After completion, the machine must be shut down, and the equipment residues must be cleaned, as well as the surrounding environment.

The original state of the machine must not be changed without permission.

Visit the molds properly according to the number, ensuring their complete quantity. They should not be thrown around or discarded carelessly.

When the mold is consumed or malfunctions, it should be reported to the team leader or general affairs in a timely manner.

When operating the grinding wheel, the body must be positioned to the side, and not stand directly in front of it. Do not press down hard; if the grinding wheel gets stuck and cannot be operated, please quickly cut off the power and notify the team leaders.

The above introduces the structural characteristics of the heading machine. If you need to know more, please feel free to Contact Us!

Latest News