Header machine manufacturer: Introduction to some information about header machines

Release time:

2021-10-31

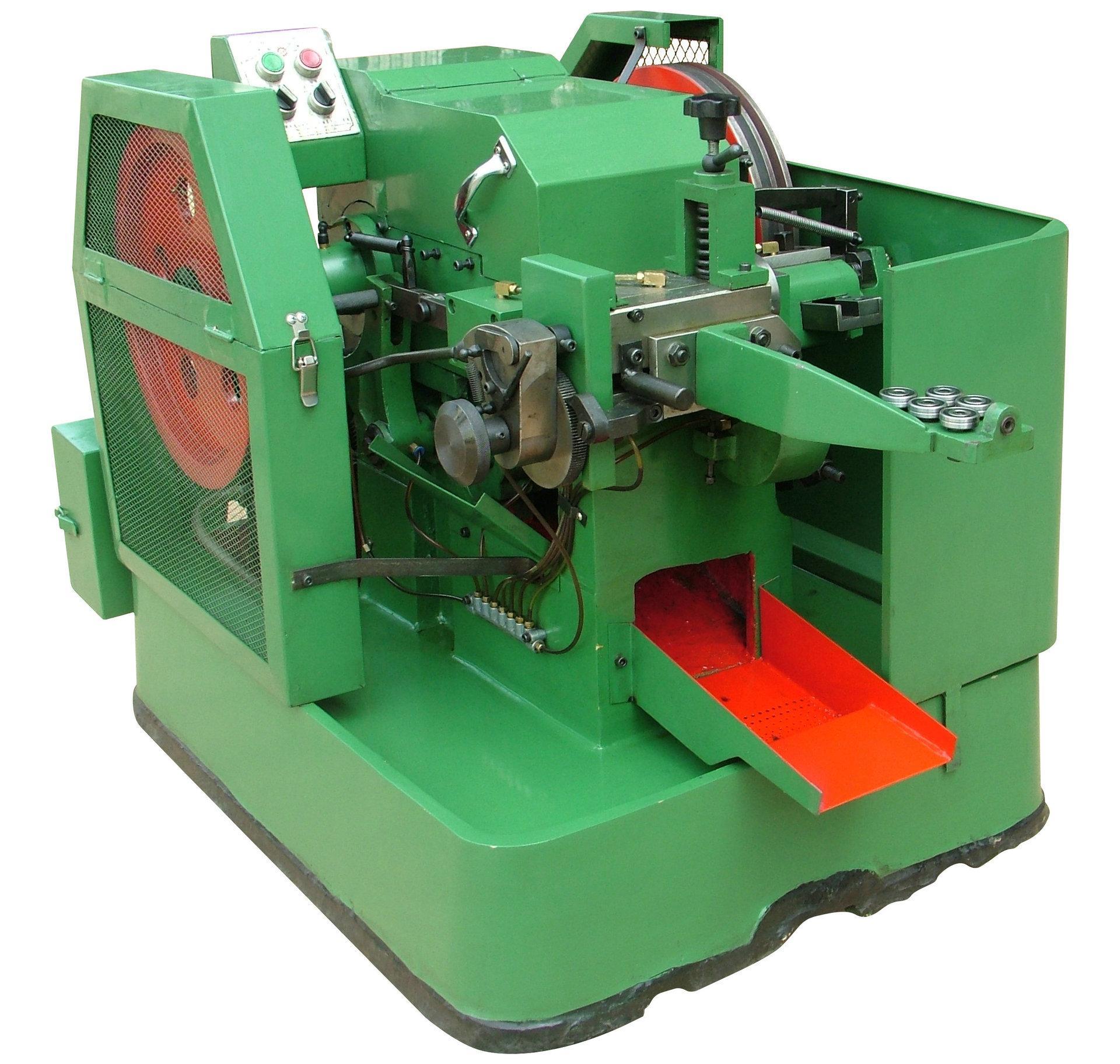

The heading machine is a type of cold heading equipment, and its function is to punch a mold and two punched products. It is mainly used for the head forming of screw products. It can forge various metal materials: ordinary steel, carbon steel, stainless steel, copper, aluminum, alloy steel, and other materials, making it widely applicable. The heading machine can manufacture common products such as ordinary self-tapping screws, electrical screws, micro screws, internal hexagon and external hexagon screws, self-drilling screws, fiberboard screws, and so on.

The screw heading machine is a type of cold heading equipment, and its function is to punch a mold and two punch products. It is mainly used for the head forming of screw products. It can forge various metal materials: ordinary steel, carbon steel, stainless steel, copper, aluminum, alloy steel, and other materials, with a wide range of applications. The heading machine can manufacture common products such as ordinary self-tapping screws, electrical screws, micro screws, internal hexagon and external hexagon screws, self-drilling screws, fiberboard screws, etc.

The structure and performance of the screw heading machine are determined by the working principle of drawing straightening, feeding, cutting, and feeding into the main mold, a single punch, and a single forging, as well as extracting two punch heads to form the blank. Its work is completed in one go, and the production capacity can reach 200 pieces per minute, which is a relatively advanced product of current technology.

The structural characteristics of the heading machine are that it is a type of screw head for screws, such as internal hexagon, external hexagon, cross type, etc. The structure of the heading machine is to load the metal wire material into the heading machine, and then the machine sets the type and length of the cutting head, and then the punching seat drives the groove of the screw head to the head shape. The punching mechanism's punching seat is equipped with a material return mechanism, which consists of at least a material return rod, a pushing element, a crank element, a shaft support element, a swinging element, a sliding element, a fixed frame, and a sliding plate.

Suzhou Huihong Machinery Co., Ltd. was established in September 2005 and is the Suzhou branch of Taiwan Huihong Industrial Co., Ltd. It is located in the Taiping Industrial Park by Yangcheng Lake in Suzhou, at the exit of the Sujiahang Expressway, with convenient transportation. The parent company, Huihong Industrial Co., Ltd., was established in 1981 in Taipei County, Taiwan. Its production equipment is advanced, manufacturing technology is strong, and testing equipment is complete, making it a professional screw machinery manufacturing enterprise integrating scientific research, development, manufacturing, sales, and service. Our main products are heading machines, cold heading machines, screw forming machines, fastener forming machines, etc. At the same time, we are also a well-known multi-station forming machine manufacturer. Leading technology, advanced equipment, scientific management, and perfect After-sale Service are your guarantee of confidence.

Latest News