Development Trends of Bolt Forming Machines

Release time:

2021-09-01

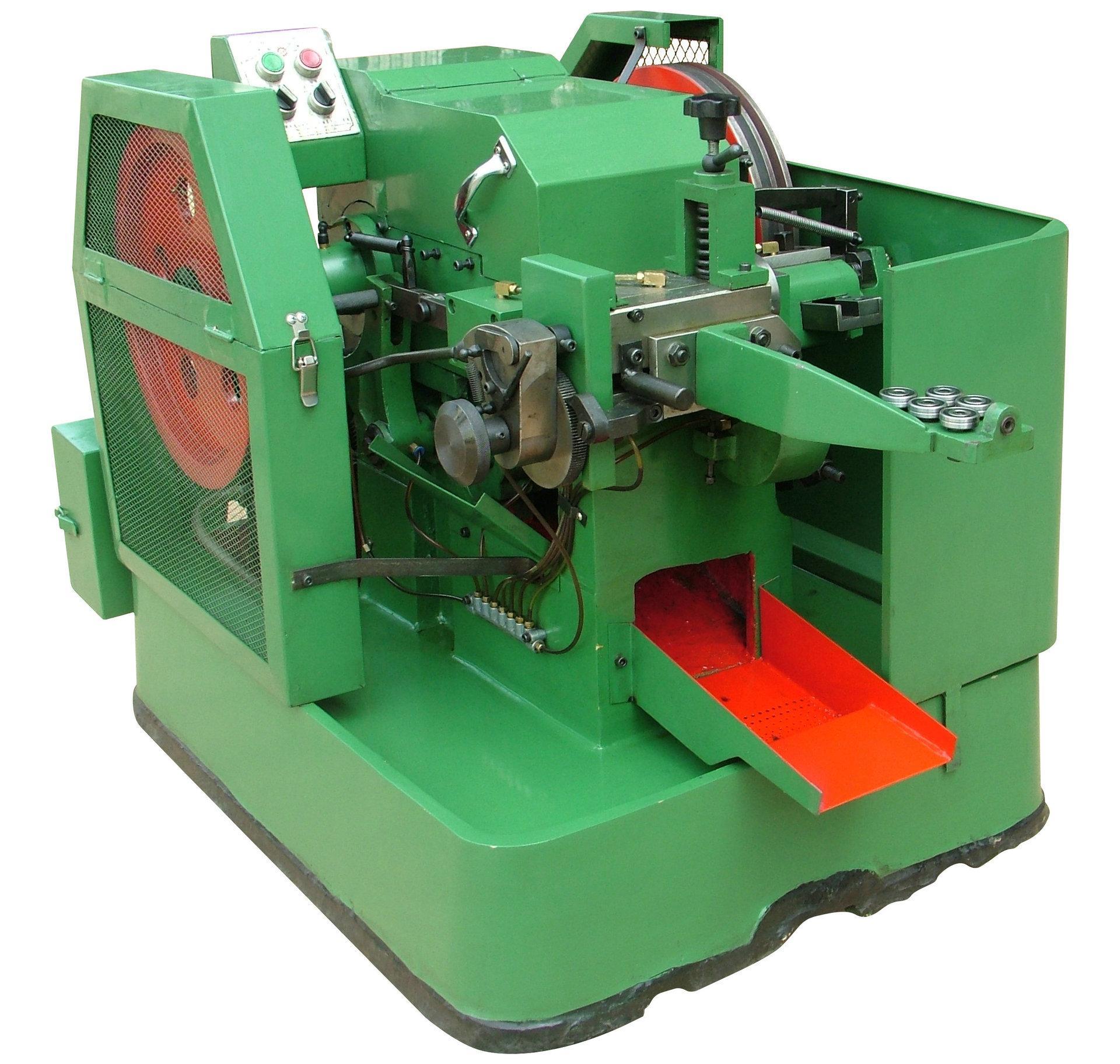

The bolt forming machine is a high-performance forging device that cuts and processes coils, capable of producing hundreds of bolts per minute.

The bolt forming machine is a high-performance forging device that cuts and processes coils, capable of producing hundreds of bolts per minute. Depending on the different die structures, various parts and bolt blanks can be produced. This article introduces the structure and characteristics of the indispensable equipment in the bolt manufacturing process—the bolt forming machine, and discusses the new functions and development trends of the bolt forming machine. In recent years, there are two technologies in the forming process that deserve special attention: one is the replacement of preparation processes and the technology to improve work efficiency; the other is high-precision forming technology.

1. Production of Bolt Blanks

Bolt blanks are mainly produced using a heading machine or a bolt forming machine, while nut blanks are mainly produced using a bolt forming machine. Simple-shaped bolt blanks can be formed through two steps of heading, while hex bolts and internal hex bolts can be formed through 3-4 steps of heading. Before the 1950s, the production of nut blanks was mainly through cutting, but now they can be formed through 4-5 heading processes.

2. Bolt Forming Machine

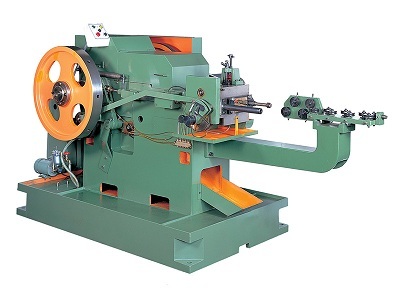

The forming machine is a horizontal press, mainly driven by a crank mechanism. The forming machine cuts the material, i.e., coils or bars, into specified lengths, and then clamps the blank between a fixed die (female die) and a movable die (male die) for forming processing. It is mainly used for the cold heading and hot heading of bolts, rivets, and components.

3. Structure of the Bolt Forming Machine

The bolt forming machine consists of a drive device, feeding device, cutting device, forging device, pushing device, and conveying device.

The drive device of the bolt forming machine is based on the main generator, transmitting power to each drive mechanism. It periodically transmits gears and cams through a pneumatic clutch.

The feeding device of the bolt forming machine consists of a straightening machine, conveying rollers, and a feeding drive device. The straightening machine is used to straighten bent coils; the conveying rollers are used to feed the wire into the roller chamber; the feeding drive device is used to adjust the transmission stroke of the wire, ensuring that the transmission length of the wire meets the specified requirements.

The cutting device is used to cut the wire into specified lengths. It is equipped with a limiter to control the material being conveyed to stop at a designated position; it also has a pusher to push the cut wire out of the shear.

The forging device converts rotary motion into reciprocating motion through a crankshaft, thereby driving the plunger that clamps the male die.

The pushing device consists of KO on the female die side and PKO on the male die side, pushing the formed blank out of the die.

The handling device is used to transport the blank to the next process. The nut forming machine is equipped with a rotating chuck that can reverse the forming direction of the male and female dies by 180°. In addition, the bolt forming machine is equipped with an open cam and a time switch to clamp the blank.

The drive system of the forming machine can be driven by a main generator to power the entire system. Each mechanism can operate normally according to the specified time.

Latest News