What are the precautions for using and maintaining the punching machine equipment?

Release time:

2021-08-18

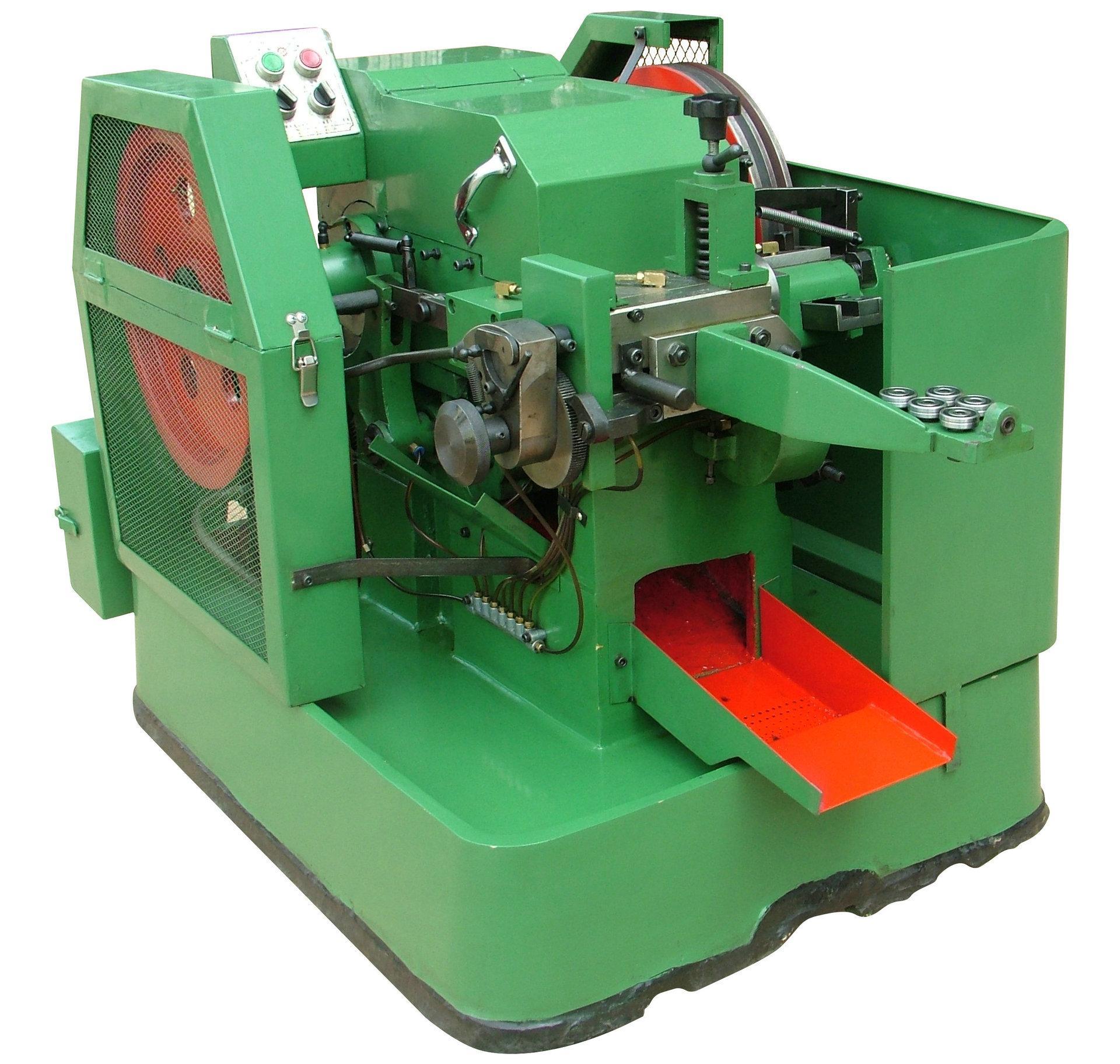

The header machine not only can work with a variety of materials, but it can also produce a wide range of products. Its mechanical equipment has advantages such as high speed, high stability, high precision, and durability.

Fastener forming

1. Purpose of the heading machine: to cold forge (or hot forge) wire to achieve the shape and length (or thickness) of semi-finished products.

2. Bolt (screw) forming (title):

Workflow:

1. Hexagon bolt (four dies four strikes or three dies three strikes)

(1) Cutting: Move the movable scissors in one direction to cut the wire stuck in the die into the required blank.

(2) First strike: The rear strike presses the blank onto the blank die, squeezing the blank to form an initial shape, and then the rear blank die pushes the blank out.

(3) Second strike: The blank enters the second strike die, the second punch squeezes the blank, and the blank takes on an oval shape, then pushed by the rear punch.

(4) Third strike: The blank enters the third strike die, through the shearing of the hexagon three-strike die, the blank's hexagonal head is initially formed. After that, the rear punch pushes the blank into the third strike die.

Material is cut off from the hexagonal head to form the hexagonal head.

2. Carriage bolt (one die and two punches)

3. Inner hexagon bolt (three dies and three punches)

4. Hexagonal washer head screw (three dies three strikes)

5. Small screw (general head shape one die two strikes)

(1) Cutting: Cut the wire stuck in the cutting die into the required blank by moving the movable scissors in one direction.

(2) First strike: The die is fixed, and the product head is initially formed by the punch for complete shaping in the next stroke. When the product has a straight slot,

one punch has a concave oval slot, and when the product has a cross slot, the other punch has a concave square slot.

(3) Second strike: After the first strike, the punch operates as a whole, the second strike moves to the front of the punch, and the second strike moves forward simultaneously, ultimately shaping the product. After that, the blank is pushed out by the rear punch.

When the heading machine forges products of different diameters, it is necessary to change the die, or when the die is damaged, it needs to be replaced. When changing the die, it often requires slight adjustments to the axial position of the large slider to ensure that the gap between the die and the die is not too large or too small, so that the die does not press against the die and the machine cannot rotate.

The heading machine must be cleaned once a day to remove dirt and ensure smooth oil flow. Before starting, lubricate the entire machine and run it idle for a few minutes before officially starting work.

The size of the end cap can be changed according to the diameter of the pipe. Internal parts are made of bearing steel and other materials. The friction plate is mainly used to prevent rotation. The oil pump is used to supply lubricating oil to the machine body and circulate, making it difficult for the internal parts to be damaged.

The heading machine can not only forge a variety of materials but also produce a variety of products. Its mechanical equipment has advantages such as high speed, high stability, high precision, and durability.

Heading machine operation inspection

(1) Check whether the bolts and nuts of each part are loose;

(2) Inject the specified lubricating oil;

(3) Rotate the flywheel by hand or momentarily about twice to see if it rotates smoothly.

Note: The machinery using air equipment should check if it is functioning normally.

Latest News