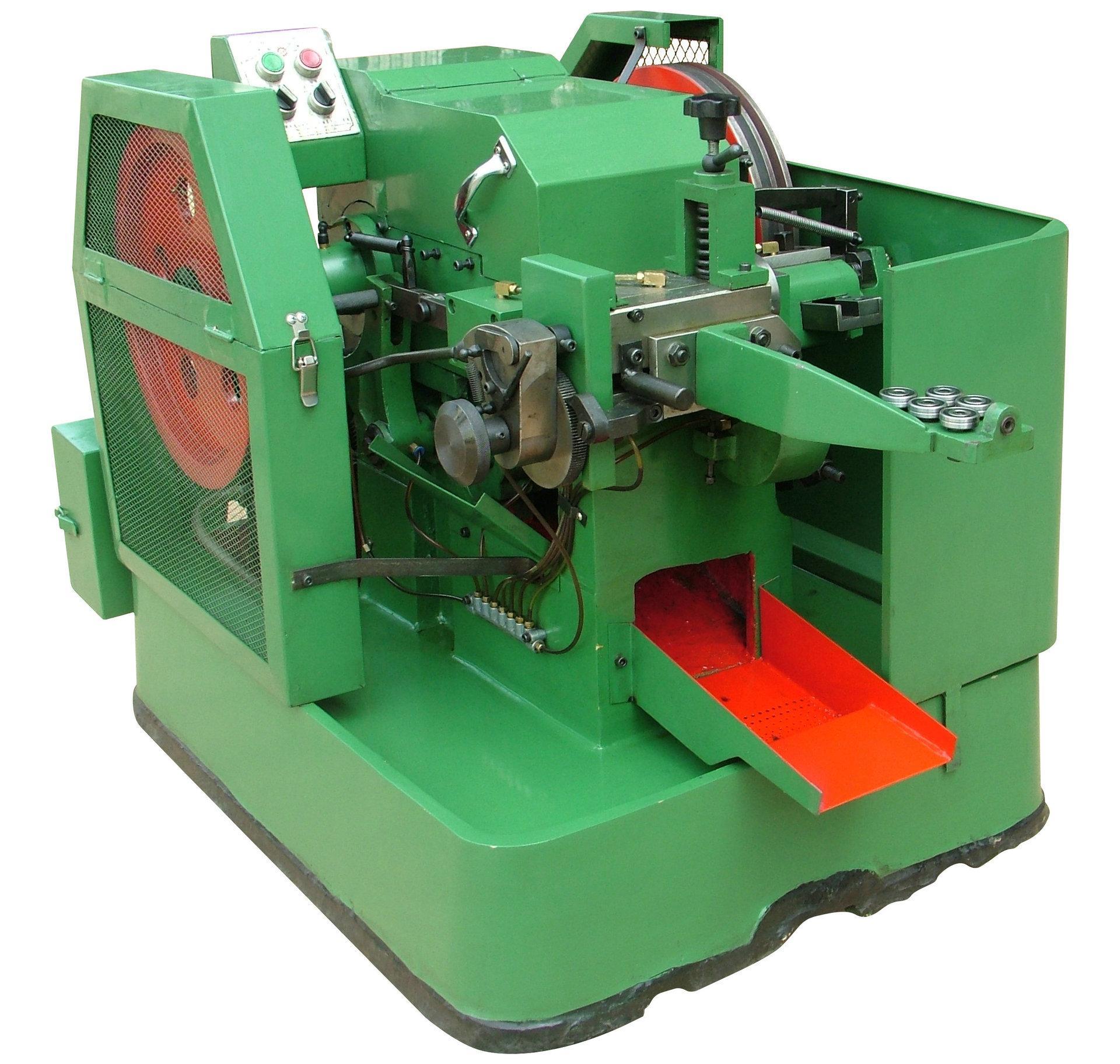

Cold heading machine manufacturers: What are the requirements for raw materials for cold heading machines?

Release time:

2021-04-19

Requirements for cold heading machine materials: 1. The chemical composition and mechanical properties of the cold heading materials for the cold heading machine should meet the relevant standards for multi-station automatic cold heading machines.

Cold Heading MachineRaw Material Requirements:

1. The chemical composition and mechanical properties of the cold heading raw materials for the cold heading machine should meet the relevant standards for multi-station automatic cold heading machines.

2. The raw materials must undergo spheroidizing and annealing treatment, and the metallographic structure of the materials should be spherical pearlite grade 4-6.

3. The hardness of the raw materials should be as low as possible to reduce the tendency of material cracking and to improve the service life of the molds, thus enhancing plasticity.

4. The full inch precision of the cold drawn materials should generally be determined based on the specific requirements of the product and the process conditions. Generally speaking, multi-stationCold Heading MachineThere are lower requirements for reducing diameter and forced dimensional accuracy.

5. The surface quality requirements for cold drawn materials are that the lubricating film should be dull and dark, and the surface must not have defects such as scratches, folds, cracks, fuzz, rust, scale, pits, and dents.

6. The total thickness of the decarburization layer in the radial direction of the cold drawn materials should not exceed 1-1.5% of the raw material diameter.

7. To ensure cutting quality during cold forming, the surface of the cold drawn materials should be harder, while the core should be softer.

8. Cold drawn materials should undergo cold top forging tests. The cold heading machine also requires that the materials have as low sensitivity to cold work hardening as possible to reduce the resistance to deformation caused by cold work hardening during the deformation process.

Latest News