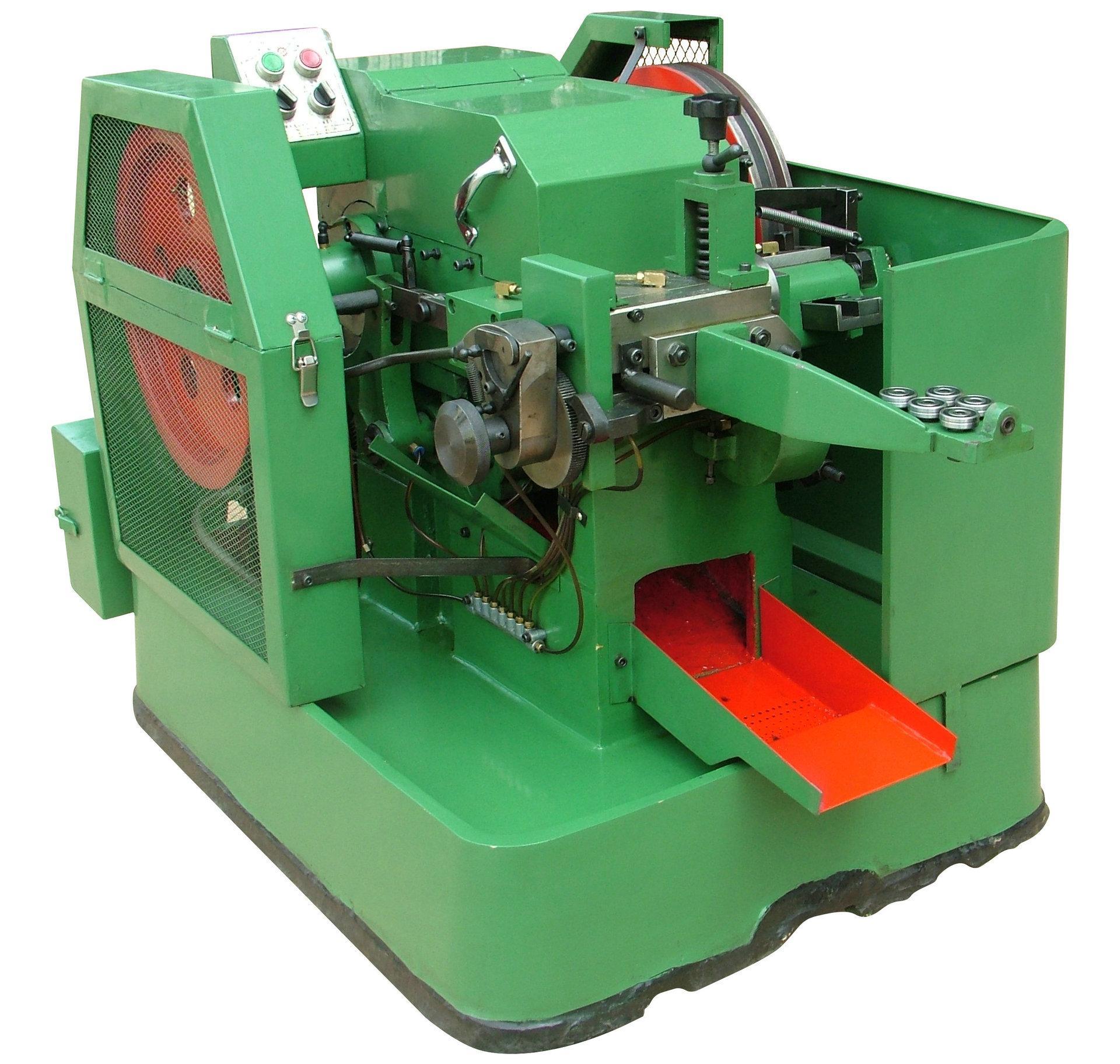

Cold heading machine manufacturer: Regular inspection of cold heading machine equipment, planned preventive checks.

Release time:

2021-04-04

The maintenance procedure for cold heading machines is a requirement and regulation for the daily maintenance of equipment. Adhering to the equipment maintenance procedures can extend the lifespan of the equipment and ensure a safe and comfortable working environment. Cold heading machine manufacturers analyze how to maintain and protect the performance and technical conditions of the equipment through wiping, cleaning, lubricating, and adjusting. This is what is known as equipment maintenance.

Cold heading machineThe maintenance program for the cold heading machine is the requirements and regulations for the daily maintenance of the equipment. Adhering to the equipment maintenance program can extend the service life of the equipment and ensure a safe and comfortable working environment. Cold heading machine manufacturers analyze how to maintain and protect the performance and technical conditions of the equipment through wiping, cleaning, lubricating, and adjusting. This is what is called equipment maintenance.

The maintenance of equipment has four main requirements: neatly placing tools, accessories, and workpieces (products), organizing pipelines and lines; maintaining the equipment. Safety compliance with safety operating procedures, not overloading the equipment, ensuring that the safety protection devices of the equipment are complete and reliable, and promptly eliminating unsafe factors; timely adding or replacing cold head forming oil and equipment lubricating oil, ensuring good lubrication, no cutting oil and dry friction, normal oil pressure, bright oil paths, smooth oil paths, oil quality meeting requirements, and ensuring that oil guns, oil cups, and felt are clean; cleaning both the internal and external parts of the equipment. The sliding surfaces, screws, racks, gearboxes, oil holes, etc. should be free of oil stains, and all components should be free of oil or gas leaks. Debris, scraps, and dirt around the equipment should be cleaned up.

Cold heading machineThe maintenance generally includes daily maintenance, regular maintenance, periodic inspections, and precision inspections, as well as maintenance of the lubrication and cooling systems. Daily maintenance of the equipment is the foundational work of equipment maintenance and must be institutionalized and standardized. The regular maintenance work of equipment maintenance should establish work quotas and material consumption quotas, and evaluate the equipment maintenance work based on these quotas.

ToCold heading machineRegular inspections are planned preventive checks. In addition to human senses, inspections also require certain inspection tools and instruments, and should be conducted according to routine inspection cards. Regular inspections are also known as periodic inspections. Regular inspections should also check the accuracy of industrial equipment to clarify the specific accuracy of mechanical equipment. Equipment maintenance should be carried out according to the maintenance program. The maintenance program is the requirements and regulations for the daily maintenance of the equipment. Following the maintenance program can extend the service life of the equipment and ensure a comfortable working environment for the equipment.

Its main content should include: daily inspections, maintenance, and the location, methods, and standards of periodic inspections. The content and methods of equipment inspection and evaluation by workers. The equipment should be tidy, clean, sturdy, lubricated, corrosion-resistant, safe, and other work contents, work methods, tools and materials used, standards, and precautions.

Latest News