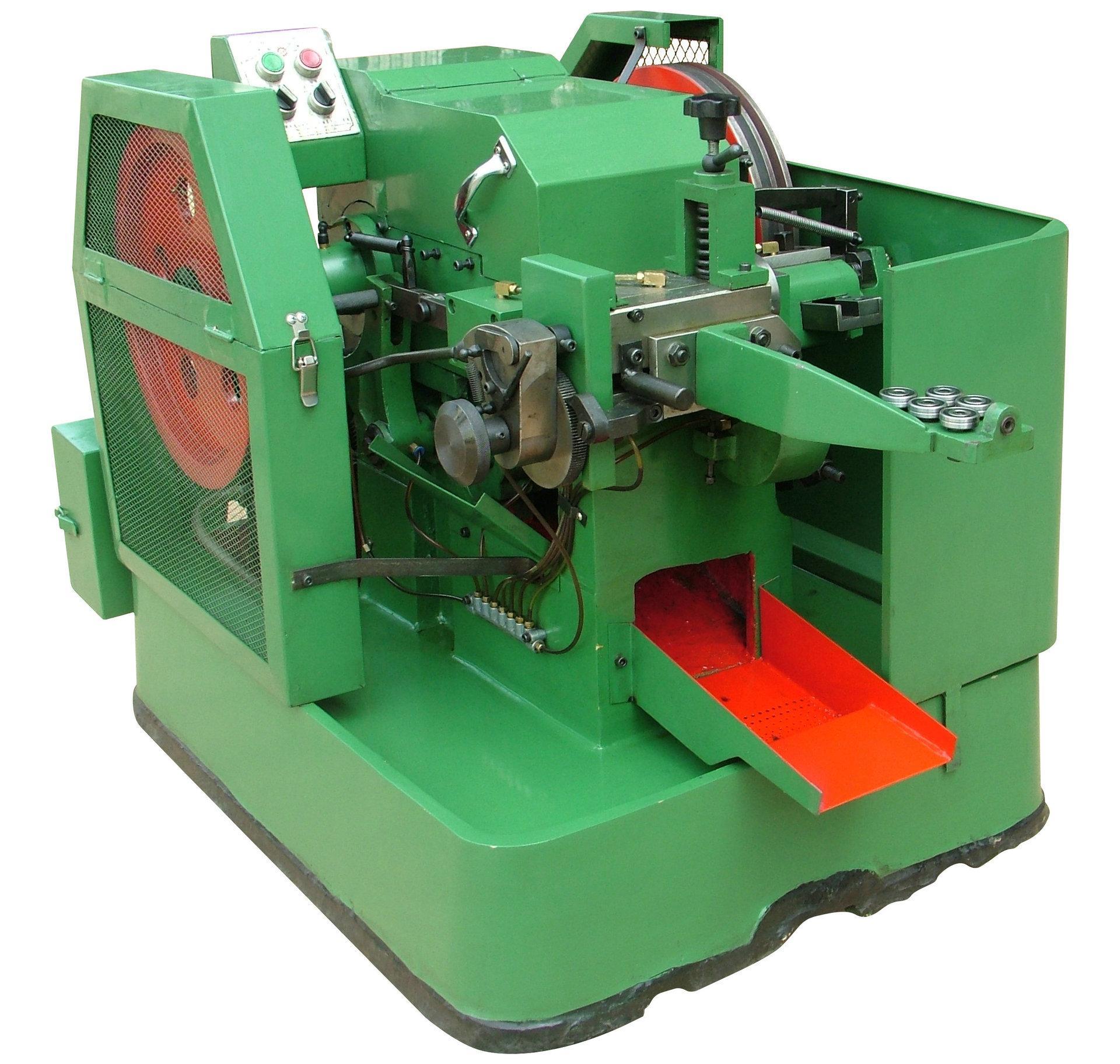

Header machine manufacturer: Steps for adjusting the header machine

Release time:

2021-03-05

The header machine can be divided into shoelace header machines and screw header machines based on different industries. Typically, when in use, it can be combined in any way and usually does not appear in an independent form. Adjustment steps:

Header machineIt can be divided into shoelace header machines and screws according to different industries.Header machineUsually, it can be combined in any way during use and usually does not appear in an independent form. Adjustment steps:

1. Fix the main mold in the main mold hole.

2. After fixing the cutting mold, install the scissors in sequence, aligning the scissors with the center hole of the main mold and the cutting mold in advance and retracting.

3. Place it on the first mold (please note that during the stroke, the first mold must not touch the main mold and scissors).

4. Calculate the required screw length as the basis for adjusting the gear level.

5. First, start the test switch to punch out the shape of the first stroke and adjust the precise center point of the first mold and the main mold.

6. Install the second mold to adjust the required head shape and adjust the center point together with the main mold.

7. The screw shape after the test run meets the standards after gauge inspection, and production can only begin after the first piece inspection.

Latest News