Cold heading machine manufacturer: Introducing the safety operation procedures for cold heading machines

Release time:

2021-02-18

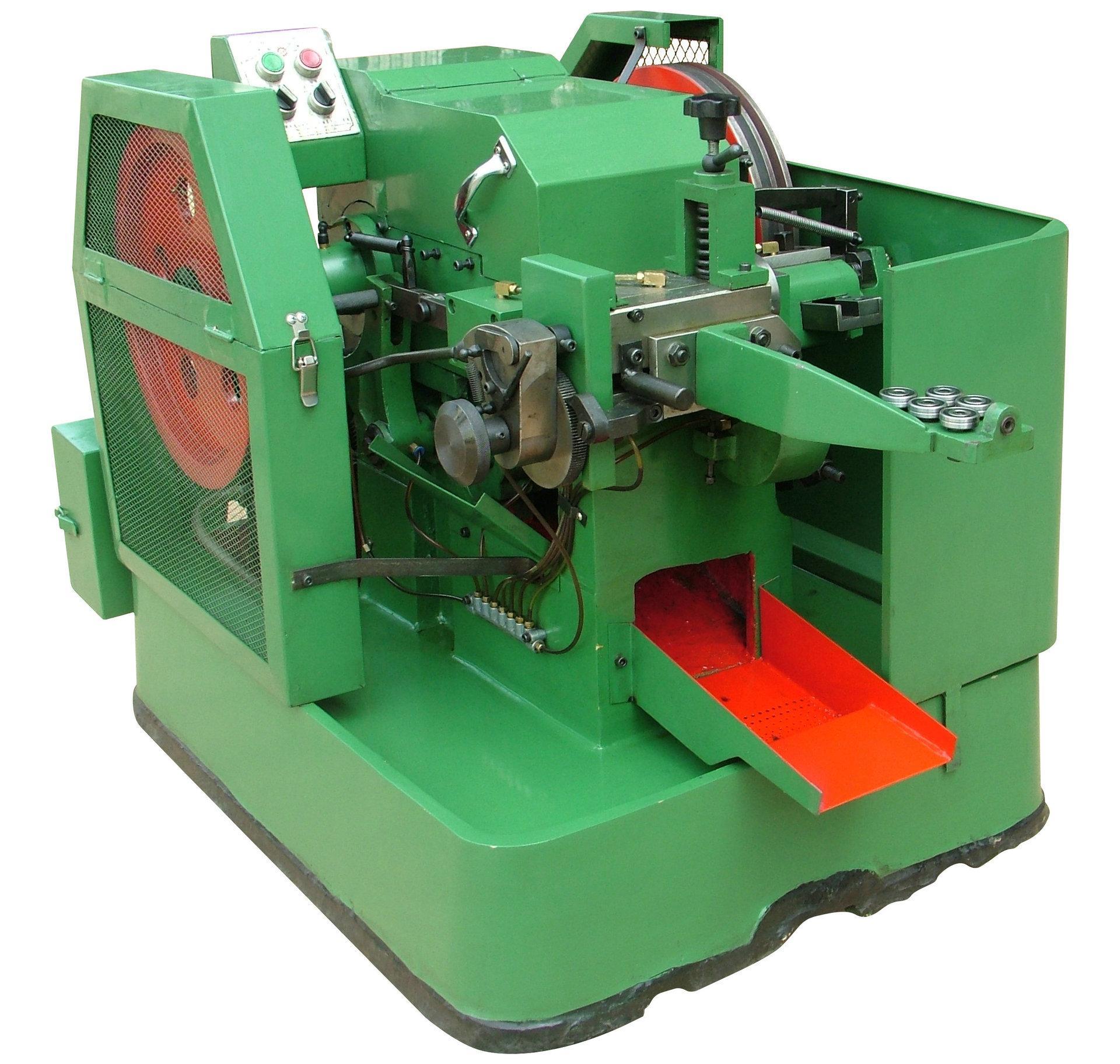

The cold heading machine is a specialized device mainly used for the mass production of fasteners such as nuts and bolts. The safety operating procedures for the cold heading machine:

Cold heading machineis a specialized device mainly used for mass production of fasteners such as nuts and bolts.Cold heading machineSafety operating procedures for

1. It is prohibited to operate with gloves.Cold heading machine.

2. It is necessary to carefully check whether the fasteners of the equipment are tightened, whether the safety protection devices are intact, and to frequently check during operation to prevent loosening due to severe vibrations, which may cause accidents.

3. After adjusting the equipment, first pull the flywheel to check whether various mechanisms are working normally, and only start the motor after removing the trigger rod. It is strictly prohibited to start the motor when triggering.

4. All faults must be eliminated, and trial heading can only be performed after a brief idle run.

5. When the equipment is running, the operator should stand in a safe position. It is strictly prohibited to pick up workpieces on the die; one can only observe the product from the lower end.

6. When changing products, the die and punch must be carefully adjusted, and components must be checked for normal operation. If a fault occurs during production, it must be stopped immediately to identify the cause and eliminate hazards.

7. The safety plate (bumper) must be equipped with protective devices to prevent accidents caused by breakage. Do not disassemble or lose any protective devices at will.

Latest News