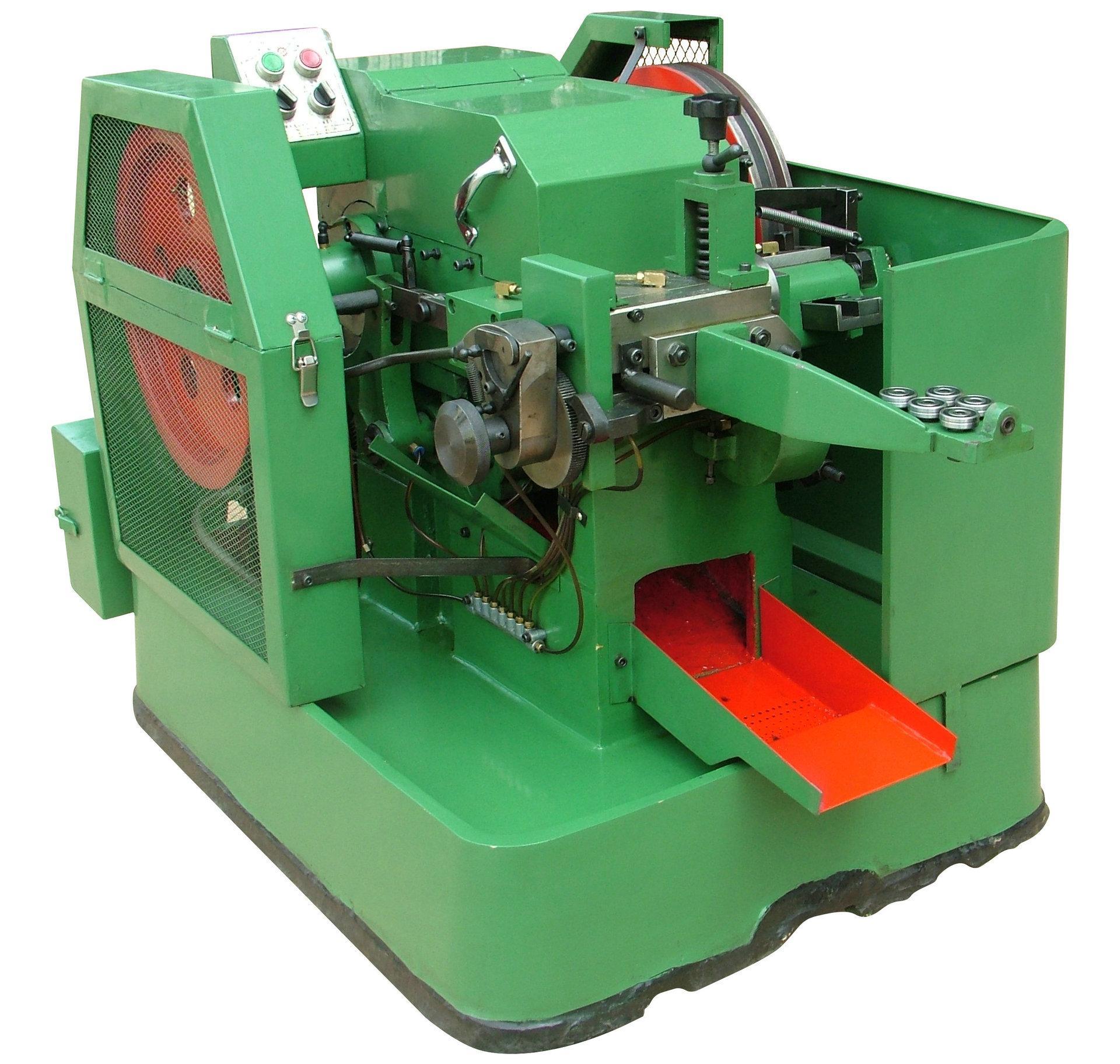

Cold heading machine manufacturer: Introducing how to operate the cold heading machine

Release time:

2021-02-03

Operation method of the cold heading machine: 1. Before starting work: 1. Check whether the knife plate, cutting tool strip, punch, mold, etc. are intact, correctly installed, and securely fixed.

Cold heading machineOperating methods of the machine:

1. Before work, do the following:

1. Check whether the knife plate, cutting tool bar, punch, mold, etc. are intact, correctly installed, and securely fixed.

2. After adjusting the cutting mechanism, the gap must be checked using a die clamp. It is strictly prohibited to start the equipment without inspection.

3. After folding the cutting tool rod, the roller in the cam slot must be removed before moving the equipment.

2. During work, ensure the following:

1. When starting the equipment, only disconnect the feeding device, and the main motor can drive the flywheel to rotate. The feeding device can only be opened after waiting for the flywheel to reach full speed. When stopping the equipment, please disconnect the feeding device first, and then stop the main motor.

2. Do not stop the slider at the "dead point" position. If the slider is at the "dead point", it can only be corrected by manually rotating the flywheel, and starting the equipment is not allowed.

3. Processed strip materials or plates must be clean, burrs on the material head must be ground off, and flat materials are not allowed.

4. Always pay attention to the working condition of the material rack. If it is messy, stop immediately. When the material is about to be processed, the tail of the material should be removed from the rack.

Latest News