Cold heading machine manufacturer: Materials and modification requirements of cold heading machines

Release time:

2021-01-14

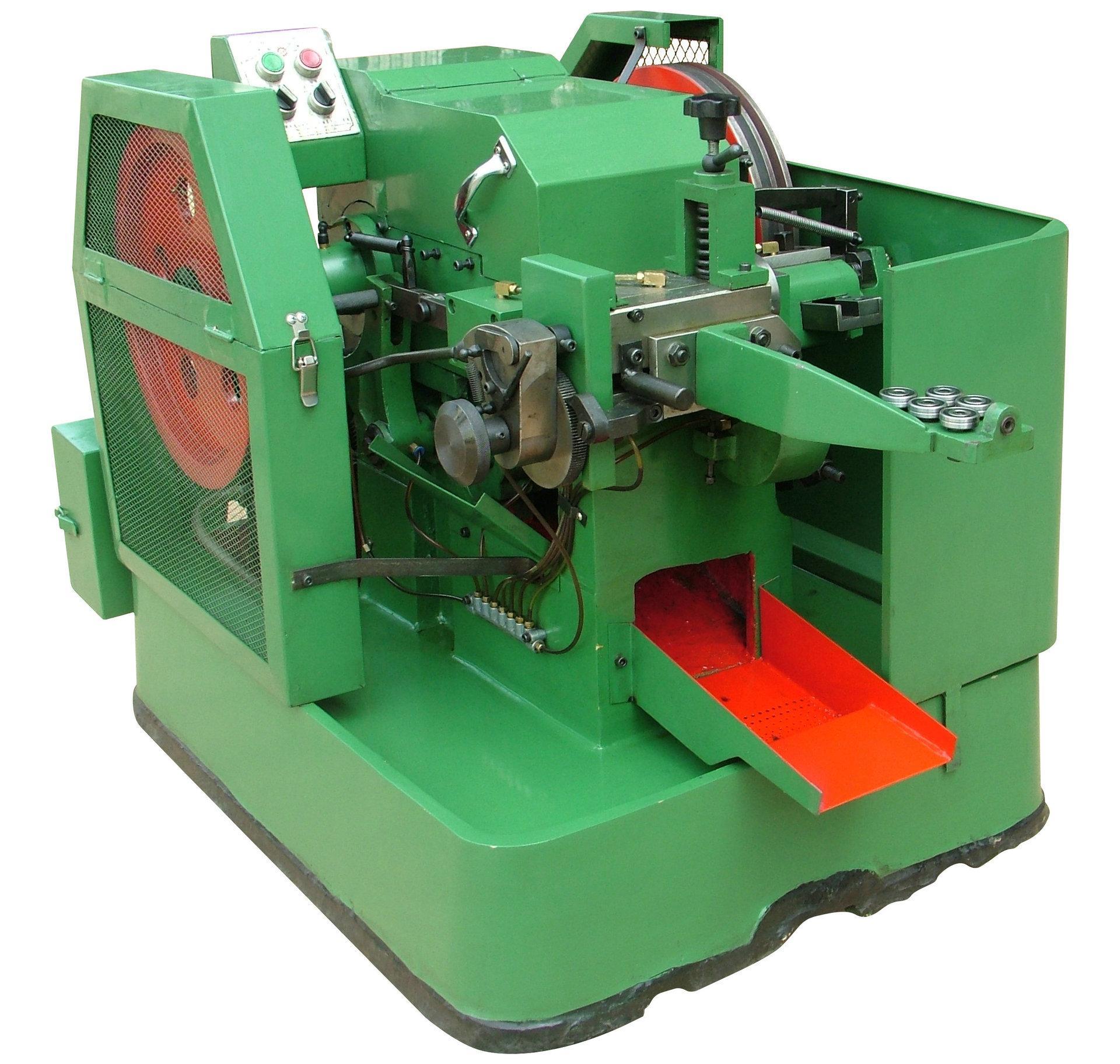

The cold heading machine is a type of stamping processing machine in mechanical manufacturing. When the raw materials remain unchanged (mainly softening or hardening and similar treatments), the material will form the desired shape (usually shaped into a "step"). Introduction to the materials of the cold heading machine: it uses cold drawn copper, aluminum wire, iron wire, etc., for automatic cold heading. It is specialized equipment for producing core aluminum rivets and semi-hollow iron rivets. The entire structure of the machine operates automatically, from straightening, material selection, secondary cutting, and forming to blanking. It has the advantages of stable forming standards and a variety of processing types.

Cold Heading MachineIt is a type of stamping machine in mechanical manufacturing. When the raw materials remain unchanged (mainly softening or hardening and similar treatments), the material will form the desired shape (usually shaped into a "step").Cold Heading MachineMaterial introduction: It uses cold drawn copper, aluminum wire, iron wire, etc., for automatic cold heading. It is specialized equipment for producing core aluminum rivets and semi-hollow iron rivets. The entire structure of the machine is automated, from straightening, material selection, secondary cutting, and forming to blanking. It has the advantages of stable forming standards and a variety of processing types.

Cold Heading MachineModification requirements:

1. The speed control system is safe and reliable, allowing for smooth and continuous changes in machine speed.

2. Continuously variable speed can be achieved without changing the mechanical transmission system of the machine tool, with a speed range of 30 to 120 pieces per minute.

3. Add a digital display device to measure the number of processed parts, which has the following functions: set the total number of workpieces to be processed, automatically stop when the set value is reached, and continuously count when feeding needs to stop or restart the machine after a fault.

Latest News