Cold heading machine manufacturer: Introducing cold heading machine processing and materials

Release time:

2021-01-11

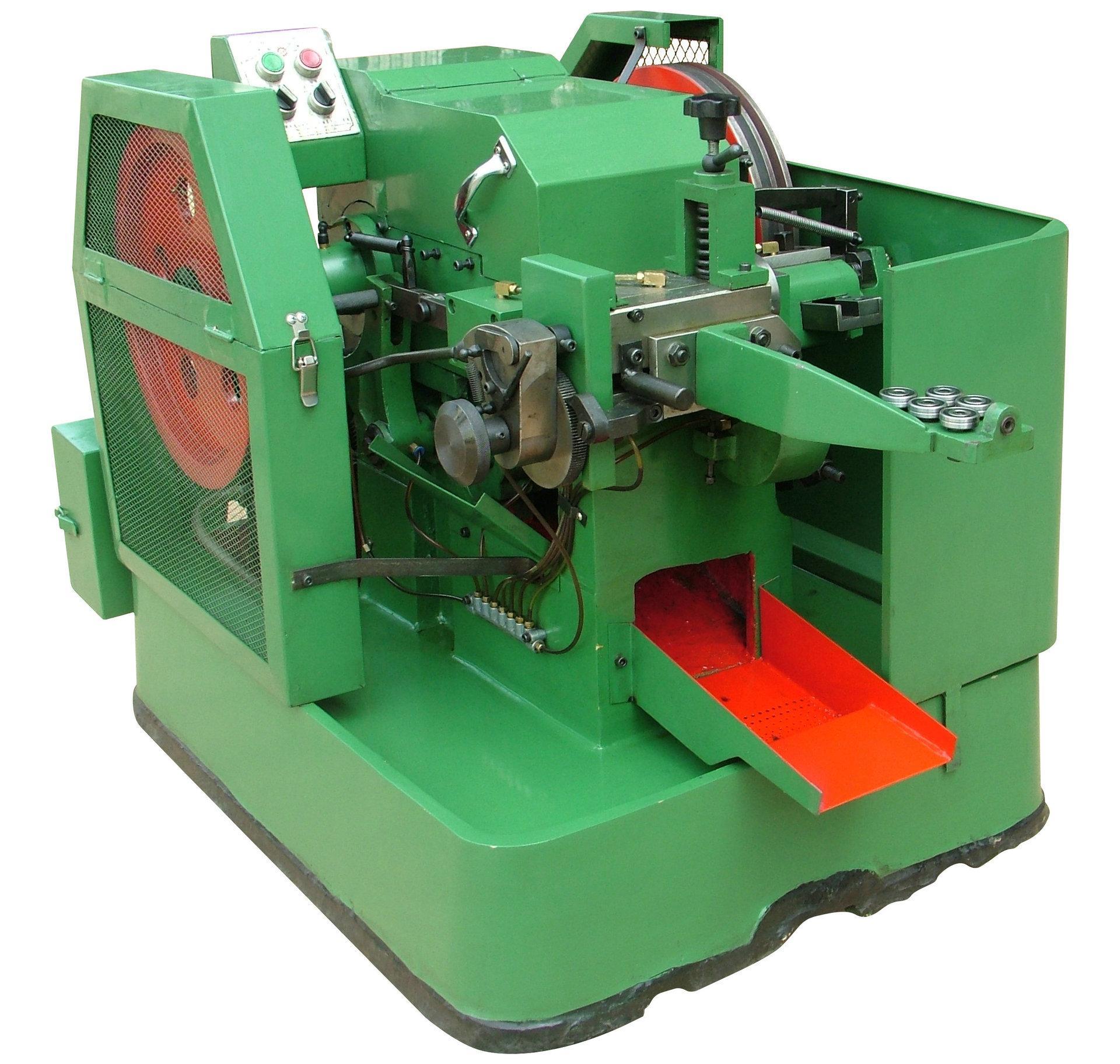

The cold heading machine is a stamping machine in mechanical manufacturing, where the raw material undergoes no changes, and when the material is softened or hardened, it is shaped into the desired form. Generally, it forms a "step." Cold heading machines are widely used in various industrial fields, such as aerospace and automotive. With the development of modern industry and the increasingly fierce competition in manufacturing, cold heading technology has become one of the important processing methods due to its economically effective processing characteristics, and it has become an indispensable technology for bulk forming of metal plastics. The structural characteristics of the cold heading machine include smooth operation, high precision, high productivity, and ease of automation. Its transmission components consist of a crank-link mechanism.

Cold heading machineIt is a stamping machine in mechanical manufacturing, where the raw material remains unchanged, and when the material is softened or hardened, it is shaped into the desired form. Generally, it forms a "step".Cold heading machineWidely used in various industrial fields, such as aerospace and automotive. With the development of modern industry and the increasingly fierce competition in manufacturing, cold heading technology has become one of the important processing methods due to its economically effective processing characteristics, and has become an indispensable technology for bulk forming of metal plastics.Cold heading machineThe structural characteristics are smooth operation, high precision, high productivity, and ease of automation. Its driving components are driven by a crank-link mechanism, cam mechanism, and gear mechanism. The motion performance is related to the realization of the whole machine's actions, which directly affectsCold heading machinethe performance and quality.

ThroughCold heading machineThe steel used for processing and manufacturing fasteners and connectors (such as bolts, nuts, screws, rivets, etc.) is called cold heading steel, commonly referred to as rivet steel. Commonly used are quenched and tempered alloy steel, low-temperature tempered alloy structural steel, low carbon low alloy high strength steel, ferrite-martensite dual-phase steel, etc. Cold heading is a plastic forming process using metal at room temperature. Using cold heading technology to manufacture fasteners not only improves efficiency and quality but also saves materials and reduces costs; however, the cold heading process requires higher quality raw materials.

Latest News