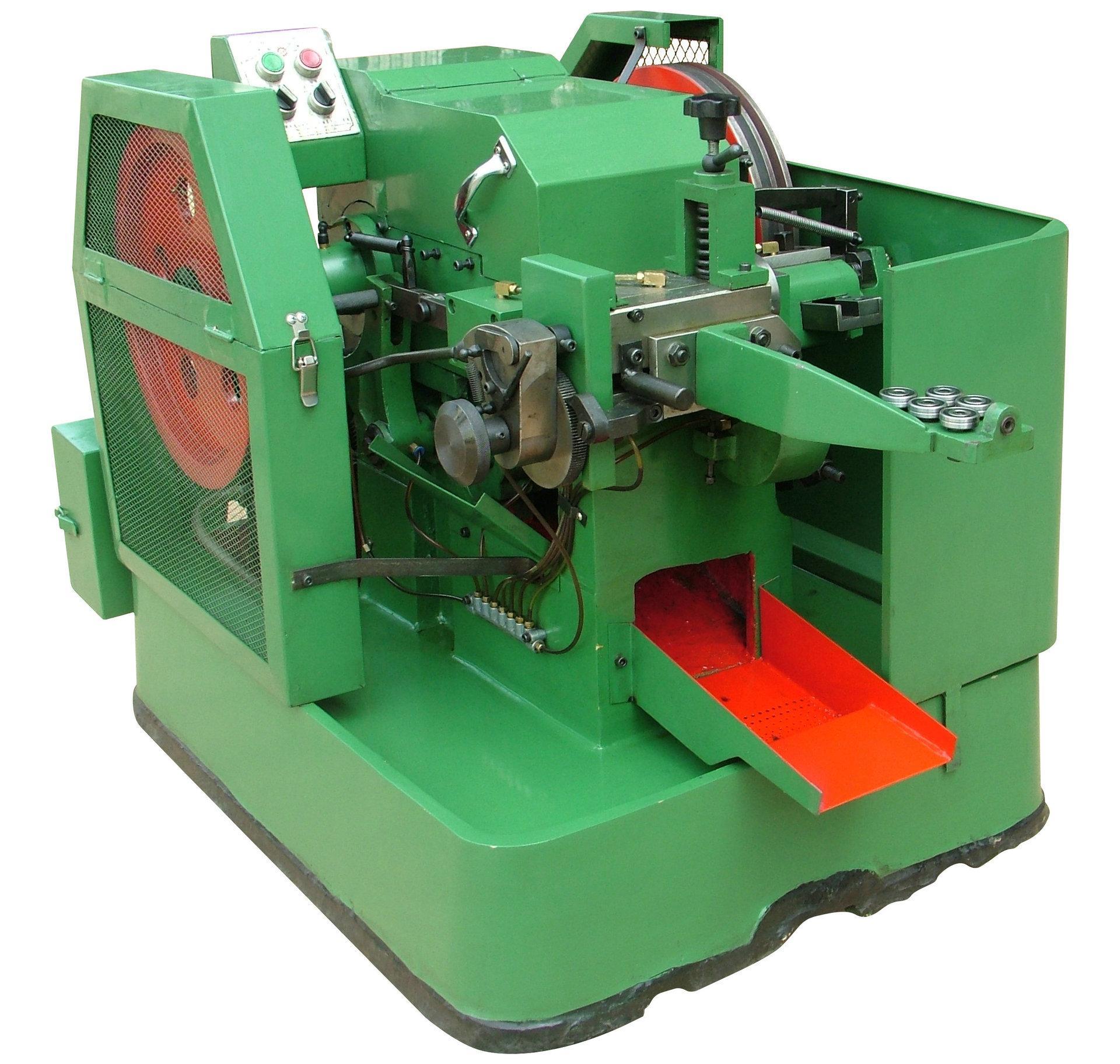

Manufacturer of header machines: Introducing the technical operation of screw header machines

Release time:

2020-12-30

The header machine belongs to cold heading equipment, and its function is to punch products with a two-stroke process. It is mainly used for the head forming of screw products. Its working principle involves straightening, feeding wire, cutting, feeding into the main mold, a single punch, and a single forging. The two-stroke forming of the blank is completed in one operation, and the production capacity can reach about 200 pieces per minute, which is a relatively advanced product of current technology.

Header MachineIt belongs to cold heading equipment, with the function of producing two products in one die. It is mainly used for the head forming of screw products. Its working principle involves straightening, feeding wire, cutting, feeding into the main die, a single punch, and a single forging. It withdraws the two-stroke forming blank, completing its work in one go, with a production capacity of about 200 pieces per minute, which is a relatively advanced product in current technology.

Header MachineIt can forge various metal materials: ordinary steel, carbon steel, stainless steel, copper, aluminum, alloy steel, and other materials, with a wide range of Applications.Header MachineIt can manufacture common products such as ordinary self-tapping screws, electrical screws, micro screws, internal hexagon screws, external hexagon screws, self-drilling screws, fiberboard screws, etc. If equipped with a top ejector device, it can also forge other non-standard special hardware products.

Header MachineThe body is welded from iron plates to form a frame, and the machine parts are made from castings. The Header size can be adjusted by changing the die according to the pipe diameter.

Latest News