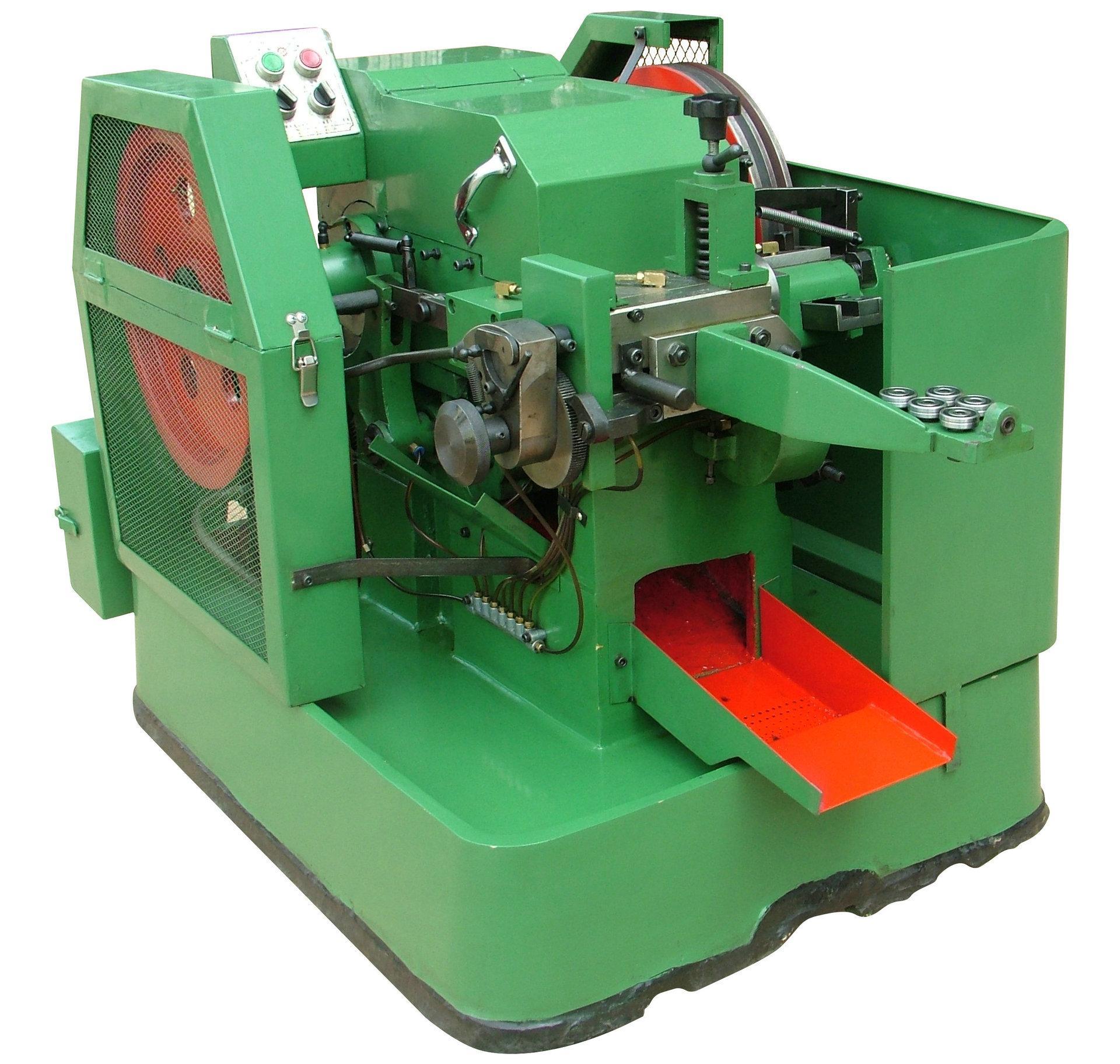

Cold heading machine manufacturer: Working principle and characteristics of cold heading machine

Release time:

2020-12-25

A forging method that thickens bars or wires at room temperature, cold heading is mainly used for manufacturing parts such as nuts, bolts, rivets, nails, and steel balls. The forging materials can include aluminum, copper, alloy steel, carbon steel, stainless steel, and titanium alloys, with a material utilization rate of up to 80-90%. Cold heading is usually carried out on specialized cold heading machines, which is conducive to multi-station, continuous, and automated production.

A forging method that thickens bars or wires at room temperature, cold heading is mainly used for manufacturing parts such as nuts, bolts, rivets, nails, and steel balls. The forging materials can include aluminum, copper, alloy steel, carbon steel, stainless steel, and titanium alloys, with a material utilization rate of up to 80-90%. Cold heading is usually carried out on specializedCold Heading Machinewhich is conducive to multi-station, continuous, and automated production.

In the cold heading method, based on its performance, hydraulic transmission can be divided into two types: hydraulic rebarCold Heading Machineandhydraulic wire.Cold Heading Machine.Cold Heading MachineIt can be classified into hydraulic transmission and mechanical transmission based on the method of power transmission. Mechanical transmission has two types: electric and manual, electric and manualCold Heading Machine, suitable for cold heading low carbon steel wire with a diameter of 4 to 5 millimeters.

Latest News