Multi-station forming machine factory: A brief introduction to multi-station forming machines.

Release time:

2020-12-07

Multi-station molding machines are commonly seen in our daily lives, with many tools around the world made from molds, and there are many types of molds. Injection molding is one of the production modes for industrial products. It is achieved through injection molding machines, which are widely operated. Injection molding machines are among the most frequently used processing machines in the plastic processing industry. Not only can a large number of products be directly produced by injection molding machines, but many plastic products can only be produced and processed through injection molding machines, which is the most obvious advantage of injection molding machines.

Multi-station forming machineIn our daily lives, many tools visible around the world are made from molds, and there are many types of molds. Injection molding is one of the production modes for industrial products. It is realized through injection molding machines, so the operation of injection molding machines is very extensive. The injection molding machine is one of the processing machines with a high operating volume in the plastic processing industry. Not only can a large number of products be directly produced by injection molding machines, but also many plastic products can only be produced and processed through injection molding machines, which is the most obvious advantage of injection molding machines.

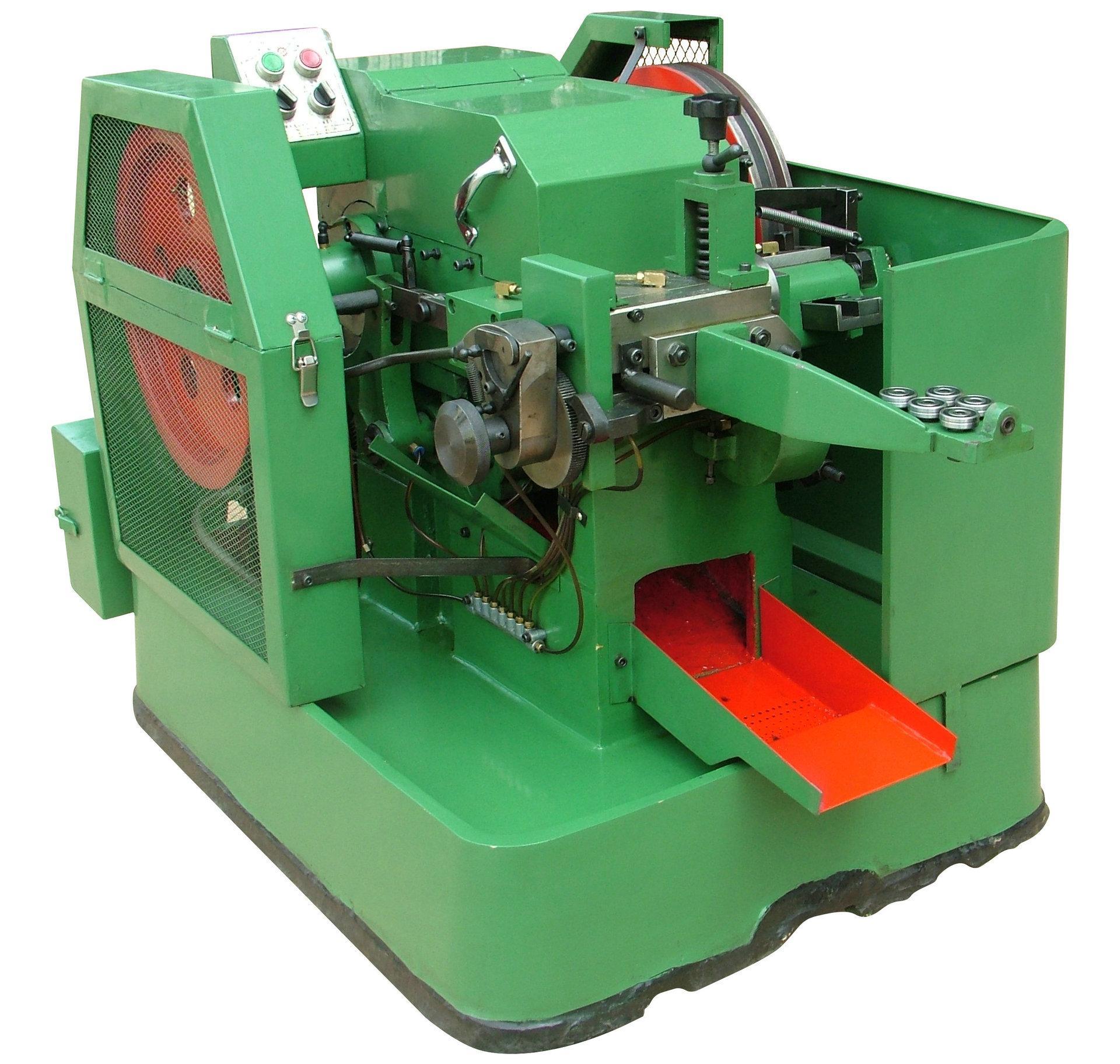

Multi-station forming machineUsed in the automotive, motorcycle, and basic machinery industries (such as chains, fasteners, bearings, socket wrenches, tools, special-shaped nuts, flange nuts, square nuts, welding nuts, locking nuts, locking nuts, locking devices, nut caps, sprockets, expansion wall lizards, self-propelling axle blocks, bicycle special-shaped parts, etc.) is the cold extrusion forming of various special-shaped and complex non-standard parts, with a wide range of applications.

Latest News