Cold heading machine manufacturer: A brief introduction to cold heading machines

Release time:

2020-12-04

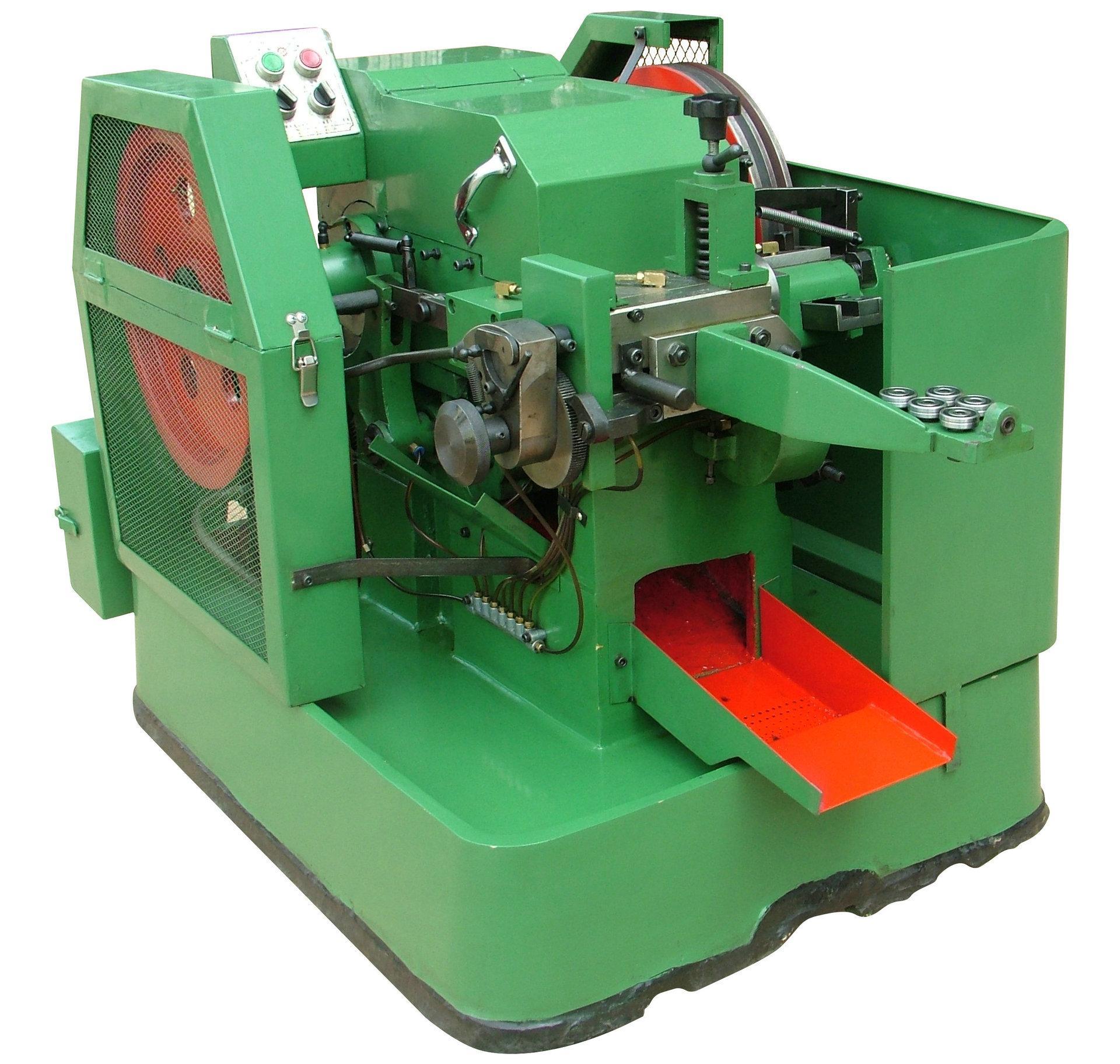

The cold heading machine is a specialized device mainly used for the mass production of fasteners such as nuts and bolts. Modern cold heading machines have evolved from simple two-station designs to multi-station ones, with newer domestic varieties including 5-die, 6-die, and extended 6-die cold heading machines. Cold heading process:

Cold Heading Machineis a specialized equipment mainly used for mass production of fasteners such as nuts and bolts. ModernCold Heading Machinehas increased from the simple two-station in the past to multiple stations, with newer domestic varieties including 5-die, 6-die, and extended 6-die.Cold Heading Machine.Cold Heading MachineProcess:

(1) According to the theory of metal plastic deformation, a certain pressure is applied to the metal blank at room temperature to cause plastic deformation in the cavity and shape it according to the specified shape and size.

(2) High-quality metal materials with good "plastic change" must be selected, such as rivet steel, which has strict standards for chemical composition and mechanical properties.

(3) The cold heading bolt and nut forming machine has multiple models and series. This equipment is reliable in performance, high in efficiency, and stable in product quality.

(4) This product has high forming and heading force, and the initial investment in equipment is large, so production specifications below M24 are the most economical.

(5) Good surface quality and high dimensional accuracy. Due to cold work hardening during the heading process, the amount of deformation should not be too large to reduce cracking. Cold heading is suitable for large quantities and various specifications of products to reduce costs.

Latest News