Header machine manufacturer: A brief introduction to header machines.

Release time:

2020-12-01

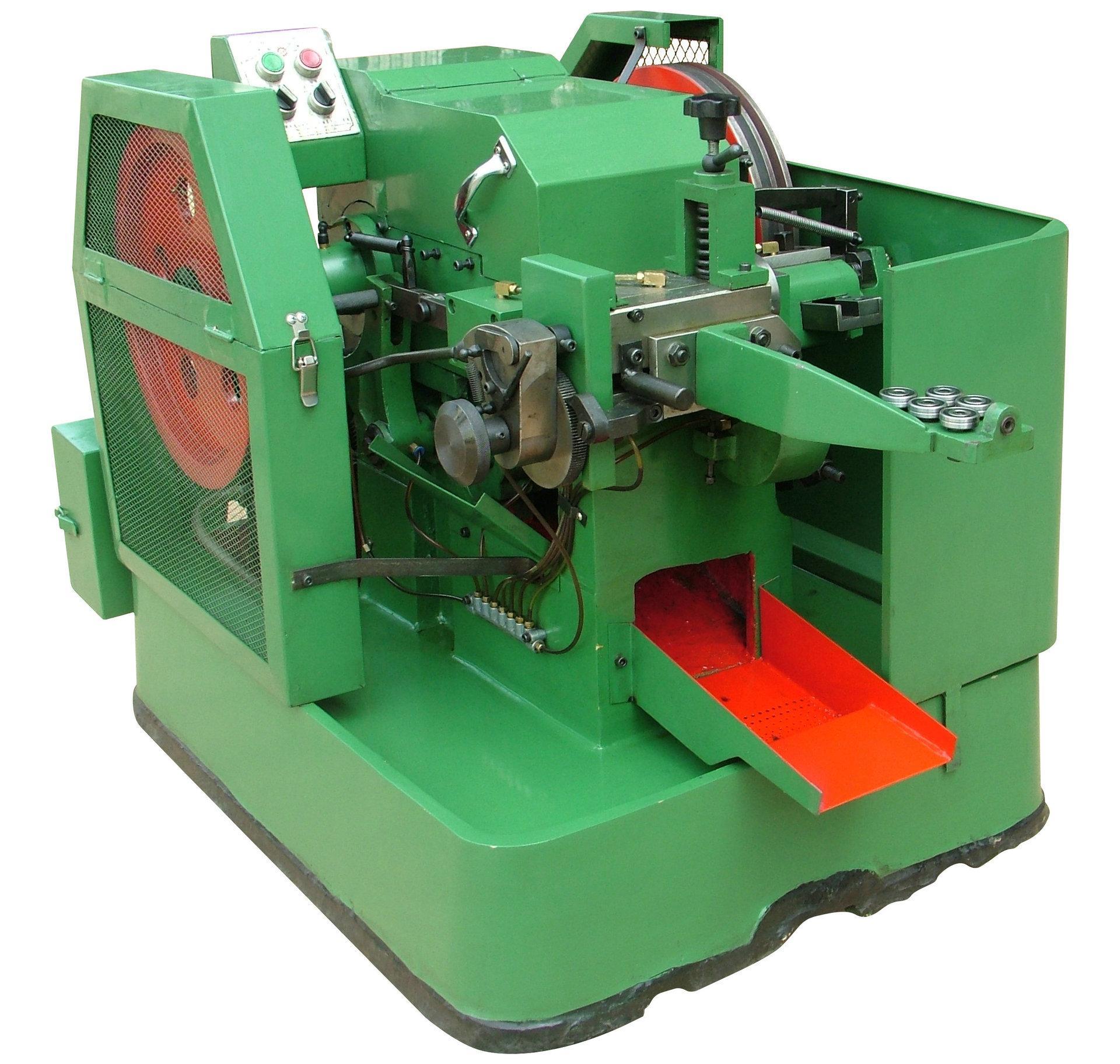

The heading machine is a type of cold heading equipment, and its function is to punch a mold and two punched products. It is mainly used for the head forming of screw products. It can forge various metal materials: ordinary steel, carbon steel, stainless steel, copper, aluminum, alloy steel, and other materials, making it widely applicable. The heading machine can manufacture common products such as ordinary self-tapping screws, electrical screws, micro screws, internal hexagon and external hexagon screws, self-drilling screws, fiberboard screws, and more.

ScrewHeader machineIt is a type of cold heading equipment, whose function is to punch a mold and two punch products, mainly used for the head forming of screw products. It can forge various metal materials: ordinary steel, carbon steel, stainless steel, copper, aluminum, alloy steel, and other materials, with a wide range of applications.Header machineIt can manufacture common products such as ordinary self-tapping screws, electrical screws, micro screws, internal hexagon and external hexagon screws, self-drilling screws, fiberboard screws, etc.

ScrewHeader machineThe structure and performance are determined by the working principle of wire straightening, feeding, cutting, and feeding into the main mold, one punch and one forging, and extracting two punch forming blanks. Its work is completed in one go, and the production capacity can reach 200 pieces per minute, which is a relatively advanced product in current technology.

Header machineThe structural characteristics ofHeader machineare the types of screw heads, such as internal hexagon, external hexagon, cross type, etc.Header machineThe structure is to load the metal wire material intoHeader machine, and then the machine sets the type and length of the cutting head, and the punching seat drives the groove of the screw head to form the head shape. The punching mechanism's punching seat is equipped with a material return mechanism, which consists of at least a material return rod, a pushing element, a crank element, a shaft support element, a swinging element, a sliding element, a fixed frame, and a sliding plate.

Latest News